The Critical Role of High Flow Hydraulic Motors in Modern Construction

Quay lại danh sáchThe relentless rhythm of construction sites – the roar of engines, the clang of steel, the deep thrum of heavy machinery in motion – is the sound of progress shaping our world. At the heart of this power lies a technology often unseen but fundamentally indispensable: hydraulic systems. And driving the most demanding tasks within these systems are high flow hydraulic motors, the unsung heroes delivering immense torque and precise control under extreme pressure. Understanding their function, particularly specialized types like the hydraulic auger motor, is key to unlocking peak performance and efficiency in today’s competitive construction landscape.

For over two decades, HEBEI LONGSHENGTENGYU PUMP INDUSTRY CO., LTD (LSTY) has stood at the forefront of power transmission solutions. Founded in 2000, LSTY embodies "power products, ensured quality, efficient service." As a leading integrated industrial supplier in China, LSTY operates through four synergistic centers – Marketing, Supply Chain Management, Manufacturing, and Integration – each a powerful engine driving towards a singular goal: offering superior products and service. With a commitment to thinking "more than customers," LSTY relentlessly pursues value addition, prioritizing customer needs and interests as its own. Their extensive scope encompasses manufacturing, development, moulding, stocking, and specialized support, underpinned by rigorous adherence to specifications and industry standards. LSTY's portfolio, including robust hydraulic motors, gear pumps, valves, cylinders, and custom-engineered solutions, is trusted globally, from Russia and Belarus to the Czech Republic and the Middle East, built on a foundation of high quality, responsive service, competitive value, and fast delivery. LSTY looks forward to forging partnerships worldwide, creating mutual value through engineering excellence.

Understanding the Core: The Hydraulic Motor in Construction

The động cơ thủy lực is the workhorse that transforms fluid power into mechanical rotation. It’s the essential component that takes pressurized hydraulic oil supplied by a pump and converts its energy into the turning force needed to drive wheels, tracks, winches, fans, and, critically, various attachments on construction equipment. Unlike electric motors, hydraulic motors excel in environments demanding high torque at low speeds, compact power density, variable speed control, and resilience against shock loads, dust, moisture, and vibration – hallmarks of the construction site.

Within excavators, hydraulic motors power the travel drives and the swing mechanism that rotates the house. In skid-steer loaders and compact track loaders, they drive the wheels or tracks directly. Cranes rely on them for hoisting and slewing. Concrete mixer drums rotate thanks to hydraulic motors. Their versatility and power transmission efficiency make them irreplaceable in mobile hydraulic applications. The core principle involves pressurized oil acting on pistons, gears, or vanes within the motor, forcing them to move and generating rotational output. The speed and torque of this output are directly controlled by adjusting the flow rate and pressure of the hydraulic fluid supplied to the motor, offering operators precise and responsive control over powerful machinery.

Unleashing Force: The Advantages of High Flow Hydraulic Motors

When standard hydraulic flow rates simply aren't enough to meet the power demands of heavy-duty tasks, high flow hydraulic motors step onto the stage. These specialized motors are engineered to handle significantly larger volumes of hydraulic fluid per minute. This increased flow translates directly into several critical advantages on the construction site:

Enhanced Power and Torque: The primary benefit. Higher fluid flow allows the motor to generate substantially greater torque output. This is crucial for applications requiring immense rotational force to overcome resistance, such as driving large drilling attachments, powering heavy mulching heads, or operating high-capacity cold planers.

Improved Productivity: With greater torque comes the ability to tackle tougher materials and complete tasks faster. A high flow hydraulic motor enables an excavator attachment to chew through rock or frozen ground more efficiently, a skid-steer mulcher to process dense vegetation quicker, or a drill rig to penetrate deeper strata with less downtime. This directly translates to more work accomplished per hour, maximizing equipment utilization and project timelines.

Support for Advanced Attachments: Modern construction increasingly relies on sophisticated, high-power attachments designed specifically to leverage high flow hydraulic motor systems. Forestry mulchers, rock grinders, large-diameter augers, and heavy-duty demolition crushers all demand the immense torque and sustained power delivery that only high-flow circuits and motors can provide. Upgrading to a high-flow system opens the door to utilizing these productivity-boosting tools.

Smoother Operation Under Load: Properly matched high flow hydraulic motors can maintain consistent power and speed even under extreme, fluctuating loads. This prevents stalling or bogging down, ensuring smoother operation and reducing operator fatigue during demanding tasks like trenching through variable soil conditions or milling rigid asphalt.

Optimized System Efficiency: While handling high flow, these motors are designed for efficiency. Utilizing a high flow hydraulic motor matched correctly to the pump and system pressure minimizes energy losses as heat, ensuring more of the engine's power is converted directly into useful mechanical work at the point of application.

Essentially, high flow hydraulic motors are the key to unlocking the full potential of modern, powerful construction equipment and attachments, enabling contractors to take on more challenging projects with confidence and speed.

Precision Power: The Specialized Role of Hydraulic Auger Motors

Among the diverse applications for hydraulic motors, one stands out for its specific demands and critical role in foundational work: the hydraulic auger motor. This motor is the dedicated power source for earth drilling and boring equipment, mounted directly on excavators, skid-steers, dedicated drill rigs, or handheld units. Its job is singular but vital: to drive the rotation of auger flights (helical drill bits) into the earth to create holes for fence posts, signposts, pilings, tree planting, soil sampling, geothermal loops, and more.

The hydraulic auger motor faces unique challenges:

High Torque at Low Speeds: Augering requires immense rotational force (torque) to cut through soil, clay, rock, and roots, often at relatively low rotational speeds. The motor must deliver this torque consistently without stalling.

Shock Loads: Hitting rocks, roots, or dense layers generates sudden, severe shock loads. The motor and its mounting must be robust enough to withstand these impacts repeatedly.

Dust, Dirt, and Moisture Ingress: Operating directly at the point of excavation exposes the motor to harsh contaminants. Superior sealing is non-negotiable for longevity.

Compact Design: Especially on excavator attachments or handheld units, space is limited. The motor must deliver high power density in a compact package.

Efficiency Under Load: Consistent performance without overheating is essential for continuous drilling operations.

Hydraulic auger motors are typically designed as low-speed, high-torque (LSHT) motors, often utilizing geroler or radial piston configurations optimized for these specific demands. They feature hardened components, advanced sealing systems, and efficient fluid paths to manage heat. The direct coupling to the auger drive head provides immediate power transmission. Choosing the right hydraulic auger motor – one with sufficient torque rating, robust construction, and reliable seals – is paramount for drilling efficiency, minimizing downtime due to motor failure, and ensuring the successful completion of foundational tasks on schedule.

FAQs About High Flow Hydraulic Motors

What are the main advantages of a high flow hydraulic motor?

The primary advantages of a high flow hydraulic motor are significantly increased torque output and power delivery. This translates directly to the ability to handle heavier workloads, operate larger and more powerful attachments (like mulchers, rock grinders, or big augers), achieve faster cycle times, and maintain consistent performance under extreme loads. They unlock higher productivity levels for demanding construction, forestry, and industrial applications where standard flow motors would struggle or fail. Efficiency gains through optimized power transmission under high flow conditions are also a key benefit.

How does a hydraulic auger motor differ from standard motors?

A hydraulic auger motor is a specialized type of động cơ thủy lực, specifically engineered as a Low-Speed, High-Torque (LSHT) unit. Unlike standard motors often designed for higher speeds and moderate torque, auger motors prioritize delivering massive rotational force at the low speeds optimal for drilling. They feature reinforced internal components (like hardened gears or pistons), robust housings, and advanced multi-layered sealing systems to withstand the extreme shock loads, abrasive contaminants (dirt, grit), and constant vibration inherent in earth drilling. Their design focuses on durability and sustained torque output under punishing conditions.

Why is reliability crucial for hydraulic auger motors?

Reliability is paramount for hydraulic auger motors because their failure causes immediate and costly work stoppages. Drilling operations are often critical path activities in construction (e.g., for foundations, pilings, fencing). A motor failure halts the entire process, delaying the project and incurring labor and equipment downtime costs. Furthermore, auger motors operate in the harshest environments – exposed to impacts, abrasives, and moisture. A reliable motor, built with quality materials (like hardened steel components), superior seals, and robust bearings, minimizes unplanned downtime, reduces maintenance frequency, and ensures projects stay on schedule and budget, maximizing the return on investment for the equipment.

Can high flow hydraulic motors improve fuel efficiency?

Yes, properly selected and integrated high flow hydraulic motors can contribute to improved overall system fuel efficiency, when matched correctly to the hydraulic pump and engine power. High-flow motors designed for efficiency minimize internal friction and fluid leakage losses. By delivering the required high torque at the point of use effectively, they allow the equipment to complete tasks faster (reducing engine run time) and prevent the system from straining or operating inefficiently under excessive pressure due to an undersized motor. The key is system optimization – pairing a high-efficiency high flow hydraulic motor with an appropriately sized pump and engine control strategy.

What factors should I consider when choosing a hydraulic motor supplier?

Selecting a động cơ thủy lực supplier demands careful consideration. Prioritize proven Quality – look for adherence to international standards (like ISO), rigorous testing protocols, and use of durable materials. Technical Expertise & Support is crucial; the supplier should understand your application deeply and offer engineering guidance for correct motor selection and integration. Reliability & Durability of the motors themselves, backed by strong warranties, is non-negotiable for minimizing downtime. Evaluate the Range & Customization capabilities – does the supplier offer motors suitable for your specific flow, torque, speed, and mounting requirements, including specialized types like hydraulic auger motors? Finally, consider Service & Global Support – prompt technical assistance, readily available spare parts, and efficient logistics for delivery are essential, especially for international operations. A supplier like LSTY, with decades of experience, integrated manufacturing, and a global support mindset, exemplifies these critical factors.

The evolution of construction equipment is intrinsically linked to advancements in hydraulic power transmission. High flow hydraulic motors represent the pinnacle of delivering brute force and controlled power where it's needed most. From driving the massive cutting drums of cold planers to powering the relentless rotation of forestry mulchers, and especially in the foundational force delivered by specialized hydraulic auger motors, these components are fundamental to modern productivity and capability.

Investing in high-quality, reliable hydraulic motors is not just a component purchase; it's an investment in uptime, efficiency, and project success. Choosing a partner committed to engineering excellence, robust manufacturing, and unwavering customer support ensures that your equipment has the reliable, powerful heart it needs to conquer the toughest jobs. Companies like HEBEI LONGSHENGTENGYU PUMP INDUSTRY CO., LTD (LSTY), with their decades of focused expertise, integrated approach, and dedication to customer value ("We think more than customers"), stand ready to provide the power solutions that keep the wheels of construction – and progress – turning relentlessly forward. When your equipment demands uncompromising power and durability, look to the core: look to high-flow hydraulic technology.

-

Tandem Hydraulic Pump for Multi - Function SystemsTin tứcJul.16,2025

-

Selecting The Right Hydraulic Motor TypeTin tứcJul.16,2025

-

How Air Directional Control Valves Power Your Pneumatic WorldTin tứcJul.16,2025

-

Engine Cooling Pump Bearing Noise CausesTin tứcJul.16,2025

-

Double-Ended Hydraulic Cylinder in Steel Rolling MillsTin tứcJul.16,2025

-

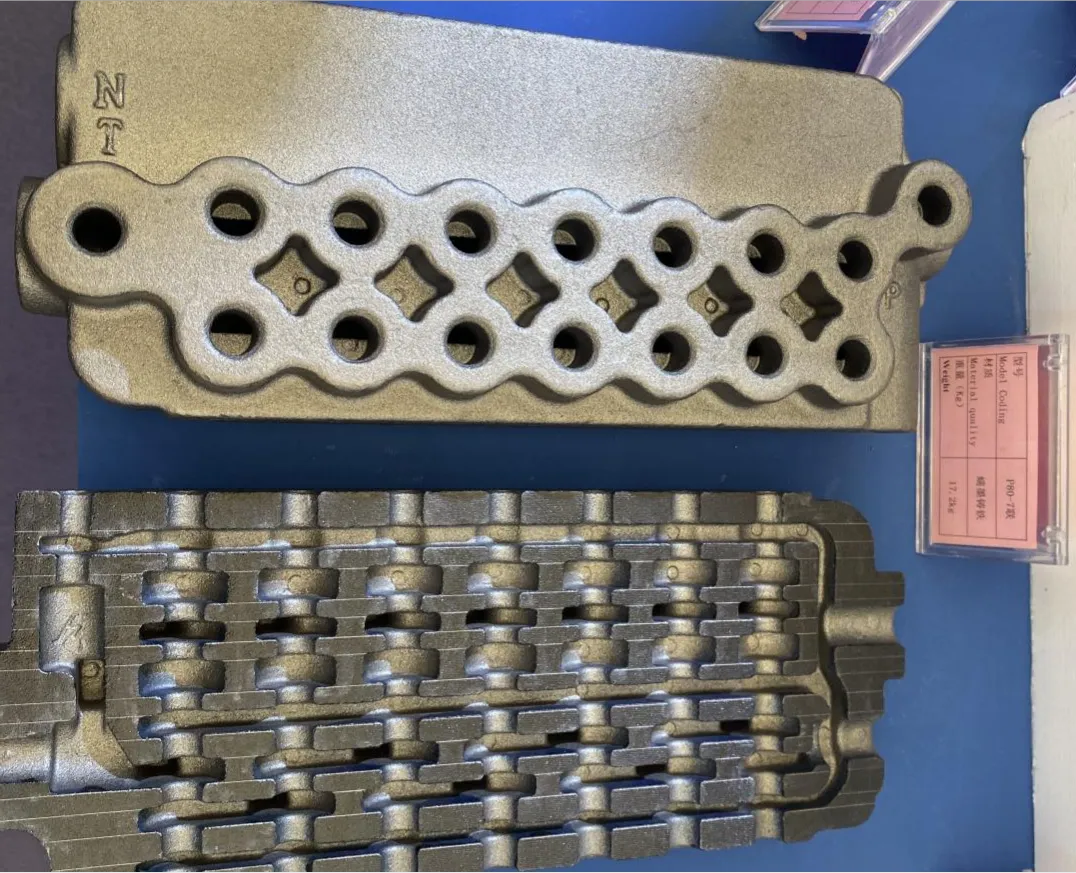

Design Optimization for Efficient Metal CastingsTin tứcJul.16,2025

-

Unveiling the Power and Precision of Hydraulic CylindersTin tứcJul.16,2025