Steel rolling mills are the backbone of industrial manufacturing, demanding precision, durability, and reliability in every component. Among the critical machinery involved, hydraulic cylinders play a pivotal role in controlling heavy loads, ensuring smooth operations, and maintaining safety. This article explores the double-ended hydraulic cylinder, a specialized variant that has revolutionized efficiency in steel rolling applications. By combining technical insights with the expertise of HEBEI LONGSHENGTENGYU PUMP INDUSTRY CO., LTD—a leader in industrial hydraulic solutions—we delve into the design, benefits, and maintenance of this advanced technology while addressing frequently asked questions to guide informed purchasing decisions.

Understanding Double-Ended Hydraulic Cylinders in Steel Rolling Mills

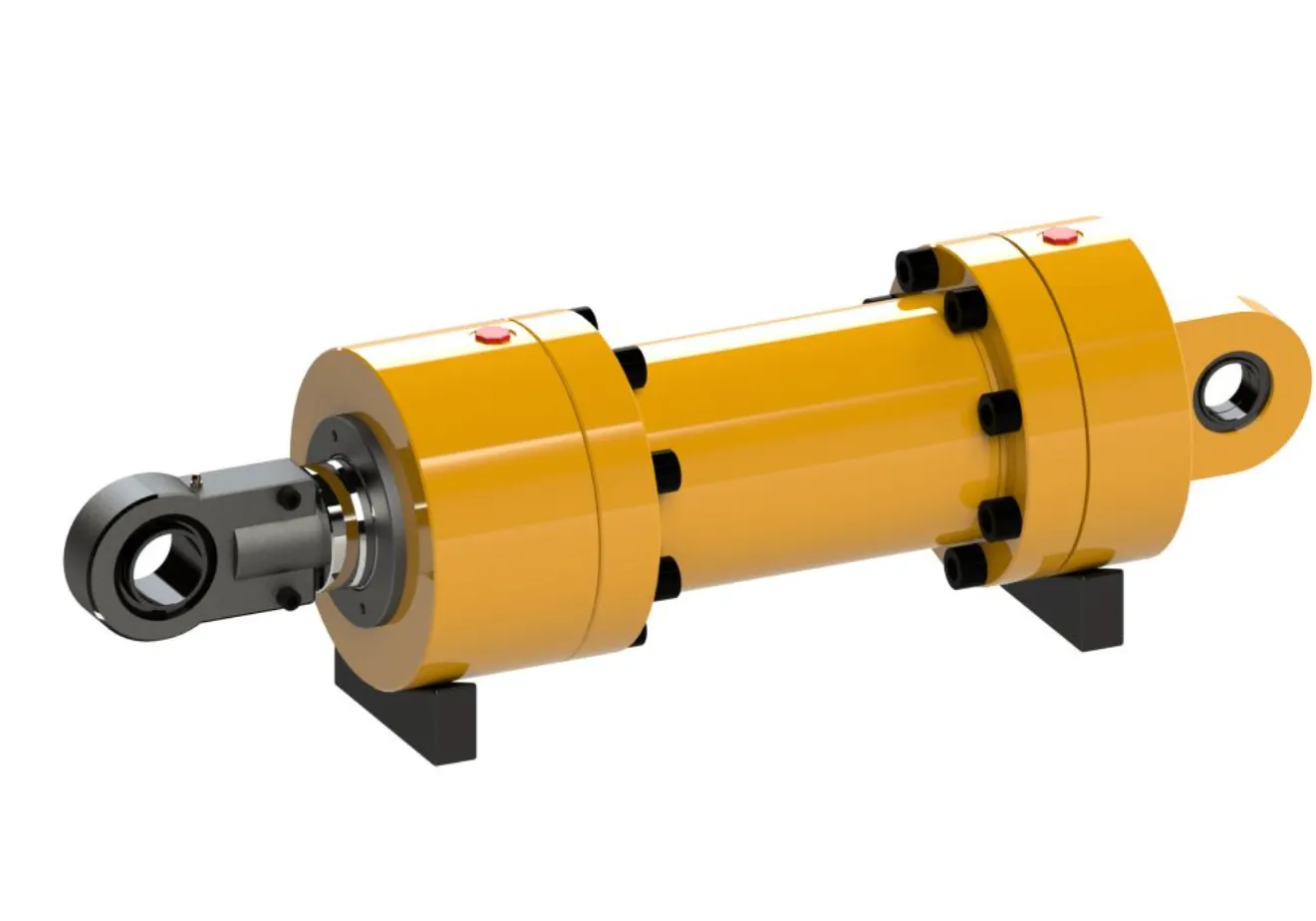

A double-ended hydraulic cylinder is a robust actuator featuring two opposing pistons or rods, enabling bidirectional force application. Unlike single-rod cylinders, which rely on one rod for extension and rely on spring force or external mechanisms for retraction, double-ended designs utilize hydraulic pressure on both sides of the piston. This symmetry ensures balanced force distribution, faster cycle times, and reduced mechanical stress—a critical advantage in steel rolling mills where heavy slabs, coils, and machinery require precise positioning.

In steel mills, these cylinders are indispensable for applications such as:

Boom hydraulic cylinders for lifting and tilting heavy machinery.

Coiler/uncoiler mechanisms for handling steel coils.

Adjustable rolls and vertical guides to maintain material alignment.

The double-ended hydraulic cylinder’s ability to generate equal thrust in both directions minimizes energy consumption and enhances longevity. HEBEI LONGSHENGTENGYU’s R&D team emphasizes that this design integrates seamlessly with modern automation systems, enabling real-time adjustments to meet the dynamic demands of steel production.

Advantages of Double-Ended Hydraulic Cylinders Over Conventional Boom Hydraulic Cylinders

Compared to traditional boom hydraulic cylinders, the double-ended hydraulic cylinder offers several distinct advantages:

Enhanced Precision and Stability: Bidirectional control reduces vibration and overshooting, ensuring stable movement of heavy loads.

Faster Cycles: Simultaneous actuation of dual rods shortens operational cycles, boosting mill throughput.

Energy Efficiency: Balanced pressure minimizes hydraulic fluid requirements and heat generation, lowering operational costs.

Longevity: Reduced mechanical wear extends maintenance intervals, aligning with HEBEI LONGSHENGTENGYU’s commitment to durable engineering.

Safety: Precise control lowers the risk of equipment failure or material misalignment, critical in hazardous steel mill environments.

HEBEI LONGSHENGTENYGU’s supply chain management center ensures that all components, including rods, seals, and pistons, are manufactured to stringent specifications, further amplifying these advantages.

Applications of Double-Ended Hydraulic Cylinders in Modern Steel Mills

The versatility of double-ended hydraulic cylinders makes them suitable for diverse roles in steel rolling operations:

Coil Handling: Lifting and transporting steel coils weighing up to several tons.

Roll Gap Adjustment: Maintaining optimal spacing between rolling mill rolls for consistent product thickness.

Shear Mechanisms: Precise cutting of steel slabs during production

Vertical Guide Systems: Stabilizing materials as they pass through rolling stands.

HEBEI LONGSHENGTENYGU’s integration center collaborates with steel mills to customize solutions, ensuring cylinders are tailored to specific load capacities, stroke lengths, and environmental conditions. For instance, high-temperature resistance coatings are applied to cylinders operating near molten steel, while corrosion-resistant materials are used in humid or acidic environments.

Maintenance and Optimization Strategies for Double-Ended Hydraulic Cylinders

Proper maintenance is vital to maximize the lifespan of double-ended hydraulic cylinders. HEBEI LONGSHENGTENYGU’s technical team recommends:

Regular Seal Inspection: Prevent fluid leakage and contamination by replacing worn seals promptly.

Lubrication Management: Use high-quality lubricants compatible with cylinder materials to reduce friction.

Pressure Monitoring: Avoid over-pressurization to prevent rod buckling or seal failure.

Environmental Adaptation: Apply protective coatings or housings for extreme-temperature applications.

Predictive Maintenance: Leverage IoT sensors to track performance metrics and preempt failures.

The company’s on-site support services include training programs for mill operators, ensuring best practices are followed. With four centers dedicated to innovation, manufacturing, and customer service, HEBEI LONGSHENGTENYGU guarantees that clients receive holistic support tailored to their needs.

FAQs About Double-Ended Hydraulic Cylinders for Steel Rolling Mills

What are the key advantages of using a double-ended hydraulic cylinder in steel rolling mills?

The double-ended hydraulic cylinder excels in force symmetry, faster cycle times, and energy efficiency. Its dual-rod design eliminates reliance on springs for retraction, ensuring consistent performance under heavy loads. This is particularly beneficial in dynamic applications like coil handling and roll gap adjustment, where precision directly impacts product quality.

How does the design of a double-ended hydraulic cylinder enhance safety in steel mills?

Bidirectional control reduces the risk of uncontrolled movements, preventing collisions or material jams. Additionally, balanced pressure distribution minimizes sudden failures, a critical factor in environments where downtime can cost millions. HEBEI LONGSHENGTENYGU reinforces safety by rigorously testing cylinders under simulated operational stresses.

Can a double-ended hydraulic cylinder replace existing boom hydraulic cylinders in my steel mill?

Absolutely. The double-ended hydraulic cylinder can be retrofitted into most systems designed for boom hydraulic cylinders, provided stroke length and pressure requirements align. HEBEI LONGSHENGTENYGU’s engineering team assists with compatibility assessments and transition planning.

What maintenance challenges are common with double-ended hydraulic cylinders?

Seal degradation and rod corrosion are primary concerns. Regular inspections, timely lubrication, and protective coatings mitigate these issues. HEBEI LONGSHENGTENYGU’s supply chain ensures access to premium materials and replacement parts, minimizing downtime.

How does the double-ended hydraulic cylinder contribute to energy savings?

By optimizing hydraulic fluid usage and reducing cycle times, these cylinders lower energy consumption by up to 20% compared to single-rod alternatives. Their efficient design aligns with global sustainability goals, appealing to eco-conscious industries.

HEBEI LONGSHENGTENYGU PUMP INDUSTRY CO., LTD combines 21 years of expertise with cutting-edge innovation to deliver high-performance double-ended hydraulic cylinders for steel rolling mills. From R&D to aftermarket support, our four-center model ensures every client receives customized solutions that enhance productivity, safety, and profitability.

By choosing our double-ended hydraulic cylinders, steel mills gain a partner committed to quality, efficiency, and customer-centric innovation. Whether upgrading existing systems or designing new facilities, trust HEBEI LONGSHENGTENYGU to power your operations with reliability and precision.

Contact us today to explore how our hydraulic solutions can transform your steel rolling process. Let’s build value together.

-

Tandem Hydraulic Pump for Multi - Function SystemsTin tứcJul.16,2025

-

Selecting The Right Hydraulic Motor TypeTin tứcJul.16,2025

-

How Air Directional Control Valves Power Your Pneumatic WorldTin tứcJul.16,2025

-

Engine Cooling Pump Bearing Noise CausesTin tứcJul.16,2025

-

Design Optimization for Efficient Metal CastingsTin tứcJul.16,2025

-

Unveiling the Power and Precision of Hydraulic CylindersTin tứcJul.16,2025

-

The Critical Role of High Flow Hydraulic Motors in Modern ConstructionTin tứcJul.16,2025