-

Inclined Shaft Axial Piston Motor

The inclined shaft type axial piston motor is a high performance hydraulic motor with the following features and advantages: High performance: with double variable axial piston structure, power transmission capacity is highly efficient. High power density and total efficiency: Good starting chara...Read more -

Hyva Tipper Pump

The Hyva tipper pump is a hydraulic pump specifically designed for tipper trucks. It is primarily used to provide hydraulic power to lift and tilt the truck bed, enabling automatic unloading of materials. Here are some key features and information about Hyva tipper pumps: Key Features: Efficienc...Read more -

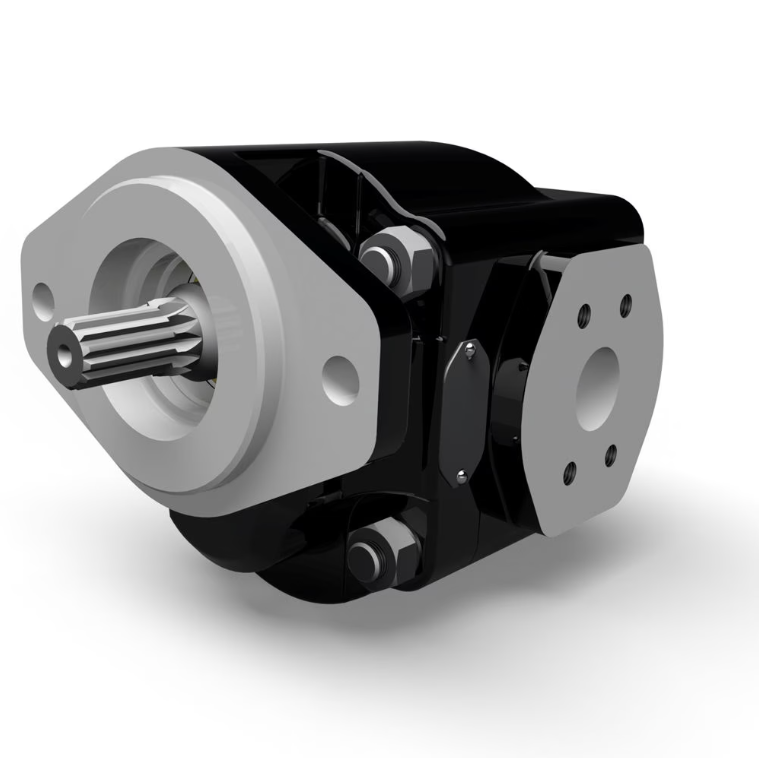

NSH Series Gear Pump

The NSH series gear pump is a type of hydraulic pump known for its reliability and efficiency in various industrial applications. These pumps are typically used for transporting lubricating oils, hydraulic fluids, and other low-viscosity fluids. They are well-regarded for their ability to handle ...Read more -

SGP Hydraulic Pump: The Key to Enhancing Dump Truck Unloading Efficiency

In the modern logistics and construction industries, dump trucks play a crucial role in providing efficient solutions for the transportation and unloading of goods. The SGP hydraulic pump, as the core component of the dump truck’s hydraulic system, is the key to achieving this efficiency. B...Read more -

Applications Of Parker Heavy Duty Iron Pumps

The applications of Parker heavy-duty iron pumps include: Construction Equipment: Parker heavy-duty iron pumps are commonly employed in various types of construction machinery such as excavators, bulldozers, and cranes to provide hydraulic power for lifting, digging, and other functions. Agri...Read more -

Advantages of the Parker Series heavy duty iron pumps

The Parker series heavy-duty iron pumps typically have several advantages, making them widely used in hydraulic systems. Here are some potential advantages of the Parker series heavy-duty iron pumps: Durability: The Parker series heavy-duty iron pumps are usually designed and manufactured with ...Read more -

Hebei Long Sheng Teng Yu Pump Industry Co., Ltd. Automechanika Shanghai 2023 exhibition concluded successfully

From 29th November to 2nd December, Frankfurt Auto Parts Fair (Automechanika Shanghai 2023) was held in Shanghai. During the four days, Hebei Long Sheng Teng Yu Pumps Industry Co., Ltd. received more than a hundred people, showing the strong company strength. Customers have praised our product...Read more -

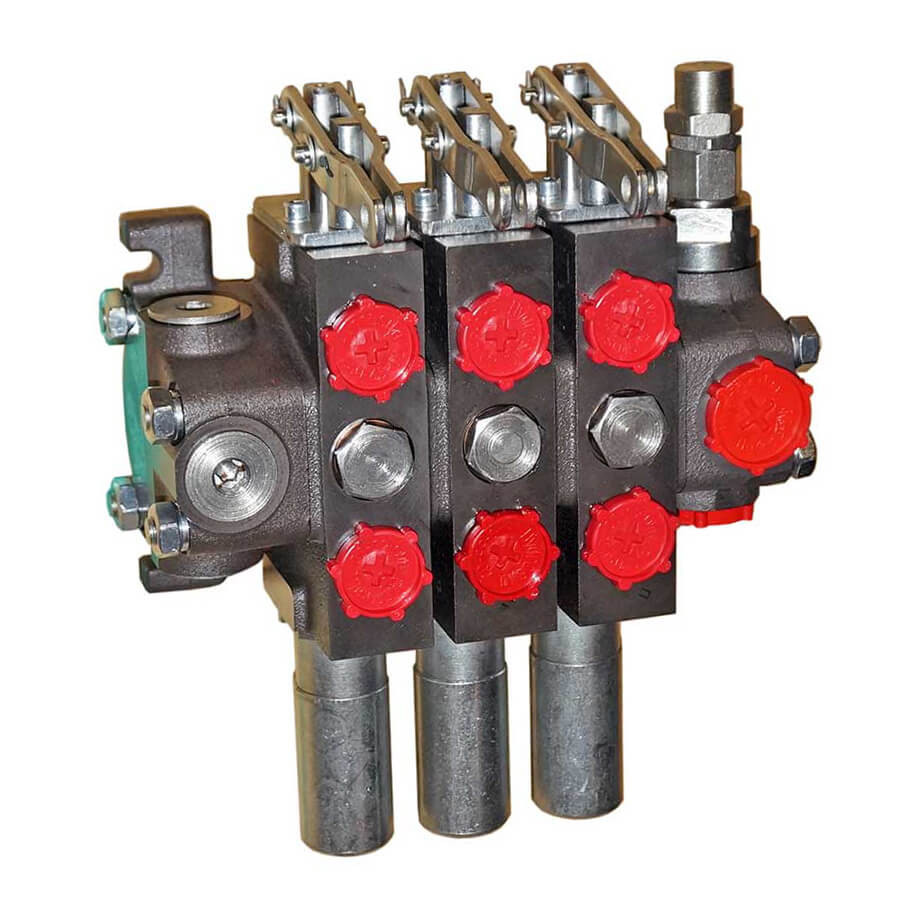

Applications of hydraulic valves

Hydraulic directional control valves are a specific type of hydraulic valve used to control the direction of hydraulic fluid flow within a hydraulic system. These valves are essential for directing fluid to various hydraulic components, such as cylinders, motors, and hydraulic actuators, to contr...Read more -

Working principle of hydraulic directional control valve

hydraulic directional control valve is a critical component in hydraulic systems used to control the flow of fluid, changing the direction of operation or performing different actions. The working principle of a hydraulic directional control valve involves changing the arrangement of internal flu...Read more -

2000 Gear Pumps ready for shipment

Production of 2,000 gear pumps for Russian customer completed. It is being prepared for shipment. Thank you for your trust and support.Read more -

Classification of hydraulic directional control valves

Manual Directional Control Valves: Hand Lever Valve: Controls hydraulic flow direction by manually rotating or moving the lever, typically used for simple manual operations. Handwheel Valve: Similar to hand lever valves but often has a larger handwheel for ease of operation. Electric Directiona...Read more -

Versatile Applications of Hydraulic Motors Across Industries

The applications of hydraulic motors are diverse and widespread across various industrial and commercial sectors. A hydraulic motor is a device that converts hydraulic pressure into mechanical motion. Here are some of its main uses: 1. **Industrial Machinery:** Hydraulic motors are extensively us...Read more

- 0086-13229068369

- autolsty@163.com

Untranslated