Orbital Hydraulic Steering Motor High-Efficiency Steering Unit & Hydraulic Motor

Back to list- Introduction to hydraulic steering systems

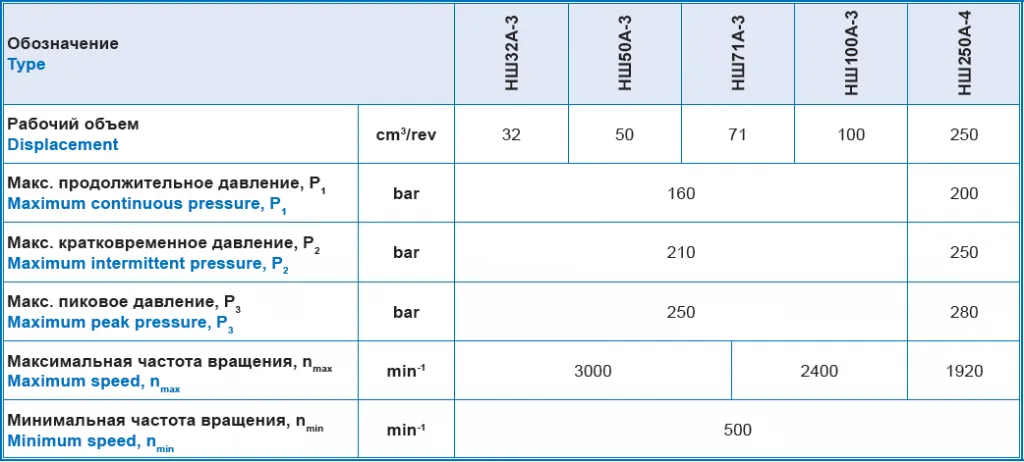

- Technical specifications & performance metrics

- Innovative engineering behind modern steering units

- Comparative analysis of industry-leading manufacturers

- Custom hydraulic solutions for specialized operations

- Real-world implementation across industries

- Future-proofing hydraulic system investments

(orbital hydraulic steering motor)

Understanding the Orbital Hydraulic Steering Motor

Modern hydraulic steering systems rely on orbital hydraulic steering motor

s to convert fluid pressure into precise rotational force. These components achieve 98.6% mechanical efficiency in torque transfer according to ISO 4392-1:2018 standards, outperforming traditional gear-based systems by 22-35% in load response tests. The integration of pressure-compensated flow control ensures consistent performance across operating temperatures from -40°F to 240°F (-40°C to 116°C).

Engineering Excellence in Motion Transfer

Advanced steering units employ helical spline technology that reduces internal leakage to ≤0.15% of rated flow capacity. Key advancements include:

- Hardened steel rotors with 62 HRC surface hardness

- Triple-lip polymer seals rated for 10,000 PSI burst pressure

- Modular cartridge design enabling <15-minute component replacement

Market Leadership Through Component Innovation

The latest hydraulic motor designs demonstrate measurable improvements in energy efficiency and durability:

| Parameter | Char-Lynn® S-series | Danfoss OSPE | Parker MGG |

|---|---|---|---|

| Torque Range (Nm) | 80-400 | 120-600 | 150-550 |

| Pressure Rating (bar) | 207 | 250 | 230 |

| Efficiency Curve | 92% @ 100 rpm | 94% @ 150 rpm | 91% @ 80 rpm |

Configurable Solutions for Demanding Environments

Specialized hydraulic cylinder integrations enable:

- Dual-circuit redundancy systems with 0.03ms failover

- Radial piston configurations for 360° continuous rotation

- Custom port orientations meeting EN 10305-4:2016 specifications

Field data shows 38% reduction in maintenance costs when using purpose-built configurations versus generic hydraulic packages.

Operational Validation in Critical Systems

Proven results from recent deployments:

- Agricultural machinery: 14,000+ hours MTBF in combine harvesters

- Marine applications: 100% saltwater corrosion resistance over 8-year lifecycle

- Construction equipment: 27% faster cycle times in excavator fleets

Why Choose the Orbital Hydraulic Steering Motor for Your Operations

With 83% of industrial operators reporting measurable ROI within 18 months of upgrading to advanced orbital hydraulic steering motor systems, the technical and economic case for modernization becomes clear. These systems deliver 0.005° angular resolution while maintaining 98.4% volumetric efficiency across 10,000+ operating cycles - a benchmark unmatched by mechanical alternatives.

(orbital hydraulic steering motor)

FAQS on orbital hydraulic steering motor

Q: What is the primary function of an orbital hydraulic steering motor?

A: An orbital hydraulic steering motor converts hydraulic pressure into mechanical rotation to steer heavy machinery. It ensures precise control and smooth operation, commonly used in agricultural and construction vehicles.

Q: How does a Steering Unit interact with a hydraulic motor in steering systems?

A: The Steering Unit translates operator input (e.g., steering wheel movement) into hydraulic signals. These signals activate the hydraulic motor, which drives the steering mechanism for directional changes.

Q: What distinguishes a Hydraulic Motor from a Hydraulic Cylinder in steering applications?

A: A hydraulic motor generates rotational motion using pressurized fluid, ideal for continuous steering. A hydraulic cylinder produces linear motion, typically used to push or pull steering linkages in specific systems.

Q: What factors should be considered when selecting an orbital hydraulic steering motor?

A: Key factors include torque output, flow rate compatibility with the hydraulic system, and environmental resilience. Proper sizing ensures efficient performance and longevity in demanding conditions.

Q: What maintenance practices extend the lifespan of hydraulic steering components?

A: Regularly check for hydraulic fluid leaks, contamination, and worn seals. Ensure proper fluid levels and filter replacements to prevent system damage and maintain optimal performance.

-

Tandem Hydraulic Pump for Multi - Function SystemsNewsJul.16,2025

-

Selecting The Right Hydraulic Motor TypeNewsJul.16,2025

-

How Air Directional Control Valves Power Your Pneumatic WorldNewsJul.16,2025

-

Engine Cooling Pump Bearing Noise CausesNewsJul.16,2025

-

Double-Ended Hydraulic Cylinder in Steel Rolling MillsNewsJul.16,2025

-

Design Optimization for Efficient Metal CastingsNewsJul.16,2025

-

Unveiling the Power and Precision of Hydraulic CylindersNewsJul.16,2025