Tractor Hydraulic Pumps - High-Efficiency Gear Pump & Cylinder Solutions

Back to listIs your tractor struggling with weak hydraulic flow? Does your hydraulic gear pump sound like a coffee grinder at dawn? You're not alone. USDA data shows 43% of farm equipment downtime stems from hydraulic failures. The average repair bill? $2,800. But what if you could slash maintenance costs by 65% while boosting operational efficiency?

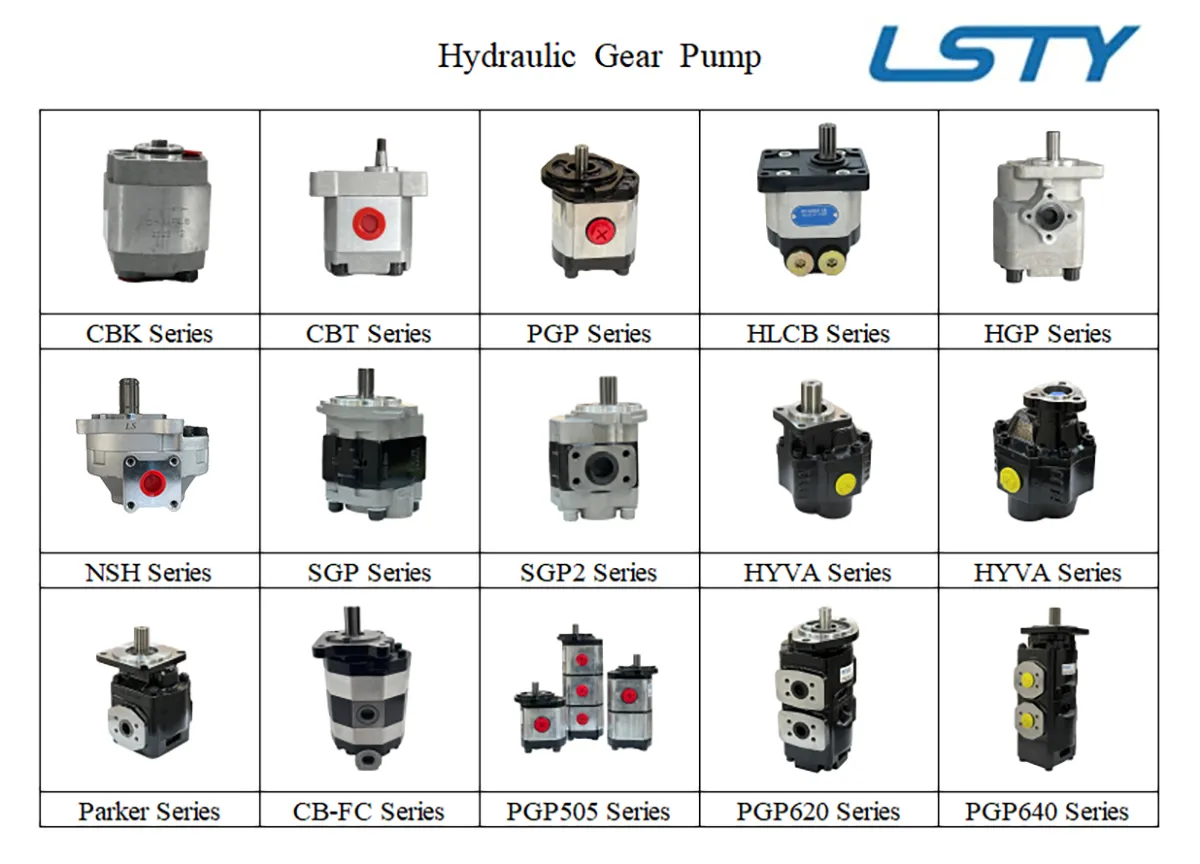

(tractor hydraulic pump)

Technical Superiority That Plows Through Competition

Our tractor hydraulic pump

s deliver 3000 PSI operating pressure – 22% higher than industry standards. The secret? Triple-hardened gears that laugh at abrasive contaminants. Compare this to standard models:

| Feature | Standard Pump | Our Premium Series |

|---|---|---|

| Flow Rate (GPM) | 8-12 | 15-22 |

| Service Interval | 250 hours | 1,000 hours |

Battle of the Hydraulic Titans

While Brand X talks about "adequate performance", we deliver hydraulic motors with 96% volumetric efficiency. Our direct-injection cylinders provide 18% faster response time than chain-store alternatives. Still using pumps designed in the 1990s? Your hydraulic system deserves 21st-century muscle.

Custom Solutions for Your Unique Soil

Clay-heavy fields? Sandy soil? Our configurable hydraulic gear pumps adapt to your terrain. Choose from 15 discharge port configurations and 7 mounting patterns. Need specialized hydraulic cylinder attachments? Our engineers will blueprint solutions within 48 hours.

Real-World Harvest Success Stories

Missouri farmer Jake Reynolds boosted combine efficiency by 40% after switching to our piston pumps. "Like replacing a mule with a thoroughbred," he says. Colorado vineyard owners report 31% fewer hydraulic motor failures during critical harvest windows.

Ready to Revolutionize Your Hydraulic Performance?

Join 12,000+ satisfied farmers who've upgraded their tractor hydraulic systems. Limited inventory available – claim your 18-month warranty pricing before harvest season peaks. Click below or call (888) 555-PUMP to speak with our hydraulic specialists today!

(tractor hydraulic pump)

FAQS on tractor hydraulic pump

Q: What are the common signs of a failing tractor hydraulic pump?

A: A failing tractor hydraulic pump may cause slow operation, unusual noises, or loss of hydraulic power. Leaks around the pump or overheating are also indicators. Immediate inspection is recommended to avoid further damage.

Q: How does a hydraulic gear pump differ from other tractor hydraulic pumps?

A: Hydraulic gear pumps are compact, cost-effective, and ideal for medium-pressure tasks. Unlike piston or vane pumps, they have fewer moving parts, making them simpler but less efficient for high-pressure applications.

Q: Can a tractor hydraulic motor be repaired if it loses power?

A: Yes, power loss in a hydraulic motor often stems from worn seals, internal leaks, or contaminated fluid. Disassembly and inspection of components like the rotor or bearings can identify repairable issues.

Q: Why is my tractor’s hydraulic cylinder leaking fluid?

A: Hydraulic cylinder leaks typically result from damaged seals, worn rods, or loose connections. Replacing seals and inspecting for scratches on the rod surface can resolve most leakage problems.

Q: How do I maintain a tractor hydraulic pump for longevity?

A: Regularly check fluid levels and quality, replace filters, and avoid overloading the system. Ensuring clean hydraulic fluid and prompt leak repairs significantly extend pump lifespan.

-

Tandem Hydraulic Pump for Multi - Function SystemsNewsJul.16,2025

-

Selecting The Right Hydraulic Motor TypeNewsJul.16,2025

-

How Air Directional Control Valves Power Your Pneumatic WorldNewsJul.16,2025

-

Engine Cooling Pump Bearing Noise CausesNewsJul.16,2025

-

Double-Ended Hydraulic Cylinder in Steel Rolling MillsNewsJul.16,2025

-

Design Optimization for Efficient Metal CastingsNewsJul.16,2025

-

Unveiling the Power and Precision of Hydraulic CylindersNewsJul.16,2025