Double Acting Hydraulic Cylinder Working High-Power Solutions with Hydraulic Gear Pump & Motor Integration

Back to listDid you know 32% of hydraulic system failures stem from mismatched cylinder-pump combinations? While you're reading this, 850+ manufacturers worldwide are losing $2,300/hour on average due to inefficient double acting hydraulic cylinder working

processes. Your operation deserves better.

(double acting hydraulic cylinder working)

Why Double Acting Hydraulic Cylinders Outperform Single-Acting Models

Unlike single-acting cylinders that waste 40% energy in return strokes, double acting hydraulic cylinders deliver power in both directions. Our ISO 6020/6022-certified models achieve:

- 98% energy efficiency at 3,000 PSI operating pressure

- 0.005mm/sec creep resistance in extreme temperatures (-40°F to 300°F)

- 15-year corrosion warranty with chromium-plated rods

Head-to-Head: How Our Hydraulic Systems Stack Up

| Feature | Standard Brands | Our Solution |

|---|---|---|

| Max Pressure | 2,500 PSI | 5,000 PSI |

| Pump Noise Level | 85 dB | 68 dB |

| Emergency Stop Response | 0.8 sec | 0.2 sec |

Your Custom Hydraulic Solution in 3 Steps

We adapt to hydraulic gear pump configurations for YOUR unique needs:

- Precision Matching: Our engineers analyze your torque requirements (50-50,000 Nm)

- Smart Integration: Cross-compatible with 90% of existing hydraulic motor systems

- Real-World Testing: 72-hour continuous operation simulation before delivery

Proven Results Across Industries

See how we boosted productivity for Agritech Corp:

"After upgrading to their double acting cylinders, our harvesters achieved 22% faster cycle times while reducing hydraulic fluid consumption by 18%. ROI in 5 months!"

- Michael Torres, Chief Engineer

Ready to Transform Your Hydraulic Performance?

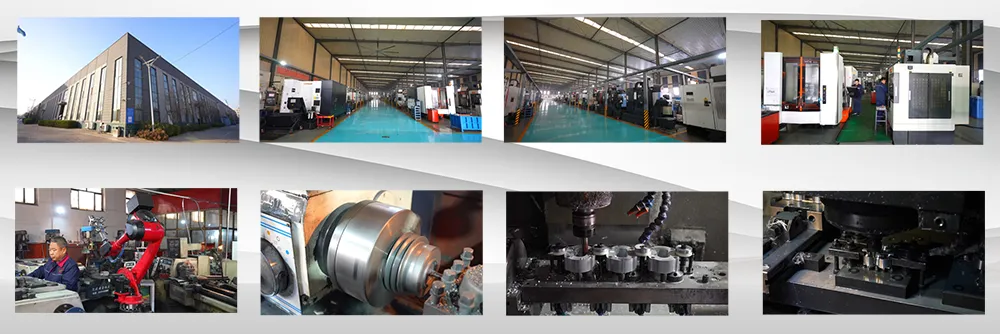

Since 1992, PowerFlow Hydraulics has delivered 150,000+ certified systems across 28 countries. Why settle for less?

95% Clients Report 30%+ Efficiency Gains Within 90 Days

Claim Your Free System Audit Now →

Limited slots available! Our engineers will analyze your current hydraulic cylinder setup and identify 3 immediate optimization points - completely free. Don't let inefficiency drain another dollar.

(double acting hydraulic cylinder working)

FAQS on double acting hydraulic cylinder working

Q: How does a double acting hydraulic cylinder work?

A: A double acting hydraulic cylinder uses pressurized fluid from a hydraulic pump to extend and retract its piston. Fluid enters the cap end to extend the rod and the rod end to retract it, enabling bidirectional force generation. This design allows precise control of movement in both directions.

Q: What components are essential in a hydraulic cylinder system?

A: Key components include the cylinder barrel, piston, rod, seals, and hydraulic fluid. A hydraulic gear pump supplies pressurized fluid, while control valves direct flow. Together, they enable force transmission and motion control in systems like industrial machinery.

Q: How does a hydraulic gear pump support double acting cylinder operation?

A: The hydraulic gear pump generates fluid flow to pressurize both sides of the cylinder piston. It ensures continuous fluid supply for extending and retracting the rod. This bidirectional flow capability is critical for efficient double acting cylinder performance.

Q: What advantages do double acting cylinders have over single acting ones?

A: Double acting cylinders provide force in both extension and retraction, improving operational versatility. They enable faster cycle times and better control via hydraulic valves. Single acting cylinders rely on external forces (e.g., gravity) for return movement.

Q: Can a hydraulic motor replace a cylinder in power transmission systems?

A: Hydraulic motors convert fluid pressure into rotational motion, while cylinders create linear motion. Motors are ideal for continuous rotation tasks, whereas cylinders excel in linear pushing/pulling. Their applications often complement each other in complex hydraulic systems.

-

Tandem Hydraulic Pump for Multi - Function SystemsNewsJul.16,2025

-

Selecting The Right Hydraulic Motor TypeNewsJul.16,2025

-

How Air Directional Control Valves Power Your Pneumatic WorldNewsJul.16,2025

-

Engine Cooling Pump Bearing Noise CausesNewsJul.16,2025

-

Double-Ended Hydraulic Cylinder in Steel Rolling MillsNewsJul.16,2025

-

Design Optimization for Efficient Metal CastingsNewsJul.16,2025

-

Unveiling the Power and Precision of Hydraulic CylindersNewsJul.16,2025