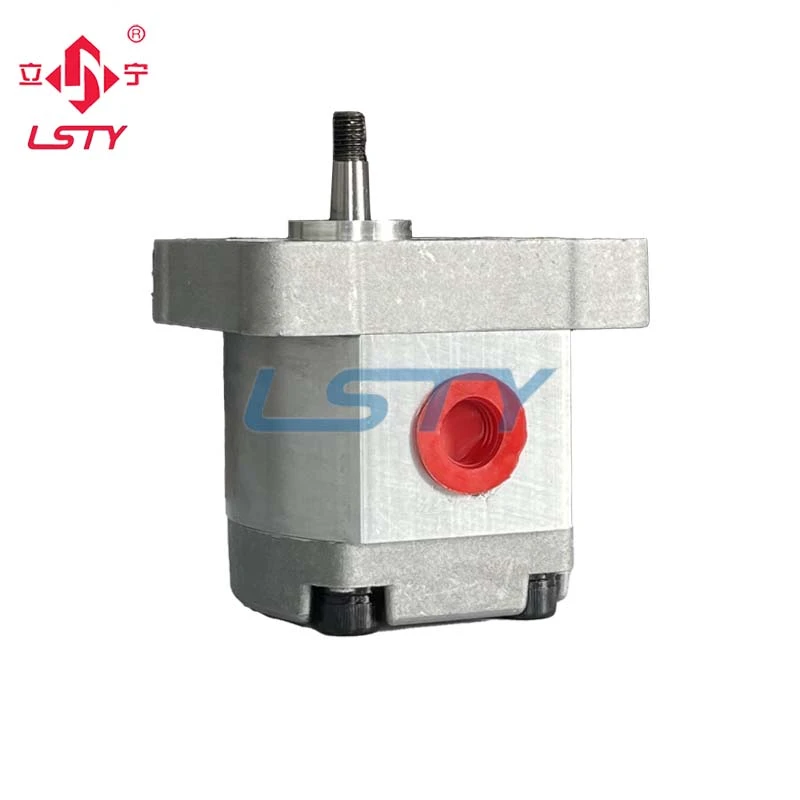

A hydraulic gear pump is a type of positive displacement pump commonly used in hydraulic systems to generate fluid flow. It operates using two meshing gears that rotate within a casing.These gears trap hydraulic fluid in the spaces between the teeth and move it from the inlet to the outlet side of the pump. As the gears turn, the fluid is displaced, creating a consistent flow of pressurized hydraulic fluid throughout the system. The hydraulic gear pump is widely used in a variety of industries, including construction, agriculture, and manufacturing, due to its simplicity, reliability, and efficiency. The two main types of hydraulic gear pumps are external gear pumps, where the gears are mounted externally to each other, and internal gear pumps, where one gear is inside the other. Hydraulic gear pumps are used to power machinery, such as forklifts, cranes, and hydraulic presses, by providing the necessary fluid pressure to actuate hydraulic cylinders, motors, and other components.

How Does a Hydraulic Gear Pump Work?

A hydraulic gear pump works by converting mechanical energy from a motor into hydraulic energy to generate fluid flow. Inside the pump, there are two intermeshing gears – one is driven by the motor, and the other is the driven gear. As the driving gear turns, it pulls hydraulic fluid into the pump through the inlet port. The meshing teeth of the gears trap the fluid, and as the gears rotate, the trapped fluid is moved through the pump to the outlet port. During this process, the fluid is pressurized as it is forced out of the pump and into the hydraulic system. The consistent flow and pressure generated by the pump allow hydraulic systems to operate machinery, control motion, and perform work, such as lifting or moving heavy loads. The simplicity of the gear pump design, which uses no valves or complicated mechanisms, contributes to its reliability and efficiency in applications that require steady and predictable fluid flow under pressure.

What Are the Advantages of a Hydraulic Gear Pump?

Hydraulic gear pumps offer several advantages, making them a popular choice for many industrial and construction applications. One of the key benefits is their simple design, which leads to lower manufacturing and maintenance costs. They are reliable, durable, and can operate in demanding environments with high pressures and variable flow rates. Additionally, hydraulic gear pumps are known for their ability to produce high flow rates in compact sizes, making them ideal for use in tight spaces or systems with limited room. These pumps can handle a variety of hydraulic fluids, including oils with different viscosities, and are relatively easy to install and maintain. Their constant flow rate also ensures predictable operation, making them suitable for systems requiring precise control. Moreover, hydraulic gear pumps have fewer moving parts than other pump types, reducing the risk of mechanical failure and minimizing the need for maintenance. This combination of durability, simplicity, and performance makes hydraulic gear pumps a trusted choice for a wide range of hydraulic systems.

What Are the Different Types of Hydraulic Gear Pumps?

There are two main types of hydraulic gear pumps: external gear pumps and internal gear pumps. External gear pumps consist of two gears that mesh externally, with one gear being driven by the motor and the other gear rotating in response. These pumps are widely used in various applications due to their simple design and reliability. Internal gear pumps, on the other hand, have one gear inside the other. The outer gear is driven by the motor, while the inner gear rotates within the outer gear, creating the necessary fluid displacement. Internal gear pumps are typically more efficient than external gear pumps, especially when handling high-viscosity fluids, and are used in applications where a smooth, consistent flow of fluid is required. Each type of pump has its advantages depending on the application, with external gear pumps being simpler and more cost-effective for general purposes, while internal gear pumps offer better performance and efficiency in more specialized systems.