The Pivotal Role of Hydraulic Cylinders in Modern Industry

In the intricate landscape of modern industrial machinery, hydraulic cylinders stand as indispensable components, converting hydraulic pressure into linear mechanical force. These robust devices are the workhorses behind countless operations, from the precise movements of automated factory lines to the colossal lifting power of heavy construction equipment. Understanding the nuances of their design, manufacturing, and application is paramount for engineers, procurement specialists, and project managers seeking to optimize performance, enhance safety, and ensure long-term operational efficiency. This comprehensive exploration delves deep into the world of hydraulic cylinders, offering insights vital for informed decision-making. We will examine the critical aspects that define their functionality, from material science and manufacturing precision to diverse application scenarios and the stringent quality control measures that guarantee their reliability. A crucial starting point for many considering new installations or replacements is to see the components in action, perhaps through a hydraulic cylinder video, which often provides an invaluable visual overview of their operation and robust construction, demonstrating the engineering prowess involved in their creation. Such visual aids are instrumental in comprehending the dynamic interplay of forces and components within these powerful linear actuators.

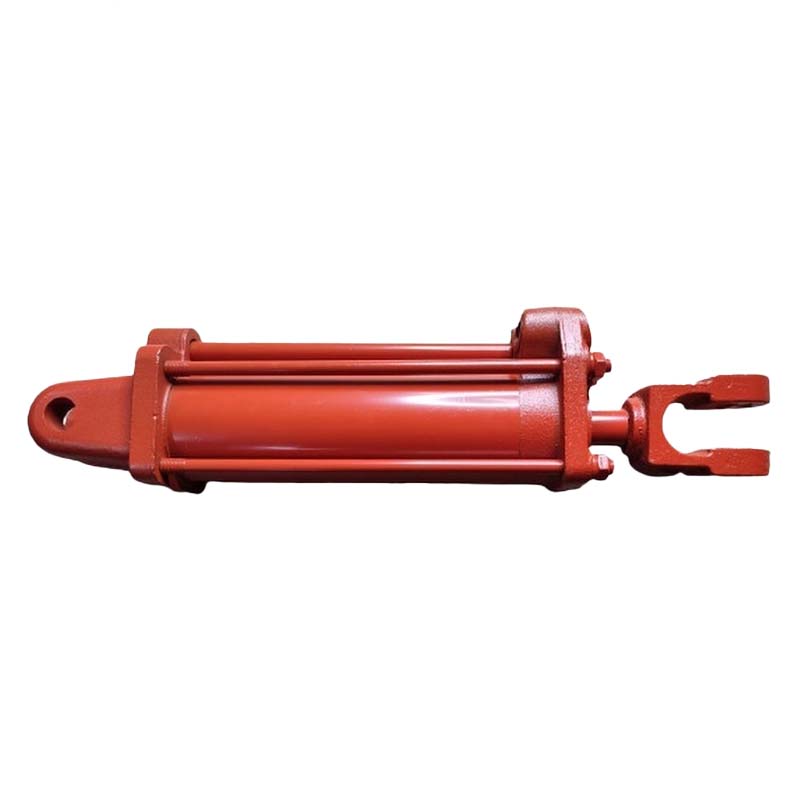

Our focus will extend to specific product specifications, highlighting how meticulous design translates into superior performance. For instance, the Hydraulic Cylinder YG75200 (Гидравлический цилиндр YG75200) exemplifies a class of high-performance cylinders engineered for demanding environments. This particular model, often featured in detailed product overviews and technical specifications, is a testament to precision engineering, designed to deliver consistent force output and extended service life under challenging conditions. Its design parameters, including bore and stroke, are optimized for a range of applications where reliability and power are non-negotiable. Furthermore, the discussion will encompass strategic considerations for hydraulic cylinder selection, detailing factors such as working pressure, mounting styles, environmental resistance, and specific industry requirements. The aim is to equip stakeholders with the knowledge to not only identify the right cylinder for their needs but also to appreciate the sophisticated engineering that underpins these essential industrial components, ensuring that every choice contributes to the overall robustness and efficiency of their hydraulic systems. This detailed analysis ensures that all critical dimensions of hydraulic cylinder integration, from initial design to long-term maintenance, are thoroughly covered, providing a holistic perspective for professionals in the field.

Industry Trends and Market Dynamics in Hydraulic Systems

The global hydraulic cylinder market is undergoing significant transformations, driven by an escalating demand for automation, robust infrastructure development, and the continuous mechanization of the agricultural sector. These market dynamics are shaping the evolution of hydraulic technologies, pushing manufacturers towards innovations that prioritize efficiency, durability, and connectivity. Emerging trends include the integration of smart sensors and IoT capabilities, enabling predictive maintenance and real-time performance monitoring, which significantly reduces downtime and operational costs. For example, modern agricultural hydraulic cylinders are increasingly being equipped with advanced telemetry systems, allowing farmers to monitor crucial parameters like soil compaction, implement depth, and even crop yield variations directly from their cabins or remote devices. This shift towards "smart hydraulics" is not merely about adding digital components but about creating interconnected systems that optimize resource utilization and enhance decision-making. The drive for energy efficiency is also paramount, leading to the development of regenerative hydraulic circuits, variable displacement pumps, and more efficient sealing solutions that minimize energy losses and reduce the carbon footprint of heavy machinery. These advancements are crucial for industries facing stringent environmental regulations and rising energy costs, making the lifecycle cost of hydraulic systems a key consideration in procurement decisions.

Furthermore, market segmentation reveals a strong demand from key sectors such as construction, mining, agriculture, material handling, and automotive. Each sector presents unique challenges and demands specific characteristics from hydraulic cylinders. The construction industry, for instance, requires cylinders capable of withstanding extreme loads and harsh environmental conditions, while the automotive industry prioritizes precision and compact designs for manufacturing processes. Geographically, rapid industrialization in emerging economies, particularly in Asia-Pacific, is fueling substantial growth, alongside steady demand from mature markets in North America and Europe that focus on upgrading existing infrastructure and adopting advanced, energy-efficient solutions. The competitive landscape is characterized by both large, established manufacturers with extensive R&D capabilities and nimble specialized firms offering bespoke solutions. This dynamic environment necessitates that manufacturers not only adhere to international quality standards like ISO and ANSI but also continuously innovate to meet evolving customer needs. Understanding these broad trends is fundamental to making informed investments in hydraulic equipment, ensuring that new acquisitions or system upgrades are aligned with future industrial requirements and technological capabilities. A comprehensive hydraulic cylinder video demonstrating these smart features and energy-saving operations can significantly aid in visualizing these advancements and their practical benefits in real-world applications.

Understanding the Anatomy and Hydraulic Cylinder Types

At its core, a hydraulic cylinder, also known as a linear hydraulic motor, is a mechanical actuator that converts hydraulic energy into linear motion and force. Its fundamental components include the barrel (cylinder tube), piston, piston rod, end caps (cylinder head and cap), and various seals. The barrel houses the piston, which divides the cylinder into two chambers: the cap end and the rod end. Hydraulic fluid, typically oil, is pumped into one chamber, exerting pressure on the piston, causing it to move and generate force. The piston rod extends from the piston through the rod end cap, transmitting this linear force to the external load. The integrity of seals—such as piston seals, rod seals, and wiper seals—is paramount for preventing fluid leakage and protecting internal components from contaminants, directly influencing the cylinder's efficiency and lifespan. Materials science plays a critical role in cylinder manufacturing; high-strength steel alloys, such as seamless cold-drawn steel for barrels and chrome-plated steel for piston rods, are selected for their exceptional tensile strength, fatigue resistance, and corrosion properties. The surface finish of critical components, particularly the bore and rod, is meticulously controlled to minimize friction, enhance seal performance, and extend component life, showcasing the high level of precision required in their production.

The diversity of hydraulic cylinder types caters to an extensive range of applications, each designed to meet specific operational demands. Single-acting cylinders extend under hydraulic pressure and retract by an external force (e.g., gravity or spring return), while double-acting cylinders use hydraulic pressure for both extension and retraction, offering greater control. Telescopic cylinders, characterized by multiple stages of telescoping sleeves, provide exceptionally long strokes from a compact retracted length, commonly found in dump trucks and cranes. Tie-rod cylinders, constructed with external tie rods to hold the end caps to the barrel, are easily repairable and suitable for medium to heavy-duty applications. Welded-body cylinders, conversely, are more compact and durable due to their welded construction, making them ideal for mobile equipment where space is limited and robustness is critical. Ram type cylinders are a specific form of single-acting cylinder where the piston rod is almost the same diameter as the bore, providing large push forces but no pull force, often used in lifting applications. Understanding these distinctions is crucial for appropriate hydraulic cylinder selection, as each type offers unique advantages in terms of force generation, stroke length, mounting options, and environmental resilience, directly impacting the overall performance and longevity of the hydraulic system. A detailed hydraulic cylinder video can visually illustrate the internal workings and operational differences between these various types, providing invaluable insight for technical personnel.

Each variant of hydraulic cylinder presents a unique set of design considerations concerning its seals, mounting, and operational characteristics, which directly influence its suitability for a given task. For instance, the choice between different rod finishes or piston seal materials might significantly impact a cylinder's performance in high-temperature or corrosive environments. Furthermore, the advancements in sealing technology, incorporating materials like PTFE (polytetrafluoroethylene) or specific elastomers, contribute to reduced friction and enhanced longevity, minimizing the risk of internal or external leakage. Mounting styles, such as clevis, trunnion, flange, or plain end, dictate how the cylinder is integrated into the machinery, affecting load distribution and overall system stability. Engineers must carefully consider the forces, movements, and environmental conditions to select the most appropriate mounting configuration. This meticulous attention to detail in design and material selection ensures that each cylinder type can withstand the specific stresses of its intended application, ranging from the repetitive cycles in manufacturing automation to the heavy, continuous duty in earthmoving equipment. The continuous innovation in materials and manufacturing processes aims to push the boundaries of durability, efficiency, and reliability, making modern hydraulic cylinders more adaptable and robust than ever before, truly setting the benchmark for linear actuation in diverse industrial settings.

The Advanced Manufacturing Process of Hydraulic Cylinders

The production of a high-quality hydraulic cylinder, such as the Hydraulic Cylinder YG75200, is a multi-stage, precision-intensive process that combines advanced metallurgy, sophisticated machining, and rigorous quality control. It begins with the meticulous selection of raw materials, primarily high-grade steel alloys specifically chosen for their mechanical properties, including high tensile strength, yield strength, and fatigue resistance, which are critical for components operating under high pressures and cyclic loads. For cylinder barrels, seamless cold-drawn tubes are preferred due to their superior internal surface finish and dimensional accuracy, reducing the need for extensive honing. Piston rods are typically made from high-strength carbon or alloy steels, followed by induction hardening and hard chrome plating to achieve exceptional surface hardness, corrosion resistance, and a smooth finish that minimizes friction and extends seal life. This material selection is foundational to the cylinder's overall performance and longevity in diverse operational environments, particularly in demanding sectors like petrochemical or mining where corrosive agents and abrasive particles are common.

The manufacturing sequence involves several critical steps. Firstly, cutting and initial machining prepare the raw stock. This is followed by precision machining, often utilizing Computer Numerical Control (CNC) machines, which are indispensable for achieving the tight tolerances required for components like pistons, glands, and end caps. CNC machining ensures dimensional accuracy, concentricity, and parallelism, critical factors for smooth operation and prevention of premature wear. The internal bore of the cylinder barrel undergoes a specialized honing process, which creates a precise, smooth, and consistent surface finish, crucial for optimal seal performance and reduced friction. For the piston rod, grinding and polishing create a mirror-like finish before it is hard chrome plated. Chrome plating, typically done via electroplating, significantly enhances surface hardness (up to 60-70 HRC), corrosion resistance, and wear resistance, especially against abrasive media. Welding techniques, such as robotic MIG/MAG or TIG welding, are employed for attaching mounts, end caps, and other structural components, ensuring strong, leak-proof joints. Post-welding, stress relieving and heat treatments might be applied to enhance material properties and prevent distortion. This complex series of operations is meticulously managed to uphold the integrity and performance of the finished product, making a detailed hydraulic cylinder video of the manufacturing process incredibly insightful for understanding the dedication to quality.

Quality control and testing are integrated throughout the entire manufacturing process, not just at the final stage. This multi-layered approach ensures that every component meets stringent international standards such as ISO 9001 for quality management systems, ANSI (American National Standards Institute) for dimensional tolerances and performance, and relevant industry-specific certifications like CE marking for European markets. Material testing includes chemical analysis to verify alloy composition, mechanical testing for tensile strength and hardness (e.g., Rockwell, Brinell), and non-destructive testing (NDT) like ultrasonic or magnetic particle inspection to detect internal flaws or surface cracks. After assembly, each cylinder undergoes rigorous performance testing. This includes pressure testing to detect leaks and verify the cylinder's ability to withstand specified working and burst pressures, often exceeding operational limits by a significant margin. Functional tests assess extension and retraction speeds, friction levels, and seal integrity under various load conditions. Endurance testing simulates long-term operation, cycles the cylinder thousands or millions of times to predict its service life and identify potential failure points under actual working conditions.

The comprehensive nature of these tests ensures that products like the Hydraulic Cylinder YG75200 are not only fit for purpose but also exceed expectations in terms of reliability and safety. The projected service life of a well-engineered hydraulic cylinder, depending on its application and maintenance, can range from hundreds of thousands to millions of cycles, translating into years of dependable operation. For specialized applications such as those in petrochemical or metallurgy industries, cylinders are designed with enhanced corrosion resistance (e.g., specialized coatings, stainless steel components) and heat resistance, tailored to specific environmental aggressors. In water and wastewater treatment plants, anti-corrosion features are paramount to prevent degradation from chemical exposure. Furthermore, modern hydraulic cylinders contribute to energy efficiency through optimized internal designs, reduced friction, and compatibility with advanced hydraulic fluids, minimizing power loss and promoting sustainable operations. These detailed manufacturing and testing protocols underpin the expertise and authoritativeness of leading manufacturers, providing a strong foundation of trust for industrial clients seeking high-performance hydraulic solutions. The meticulous attention to detail at every stage, from material sourcing to final testing, is what defines a truly high-quality hydraulic cylinder, ensuring its performance aligns with the most demanding industrial requirements.

Technical Parameters and Performance Metrics

When considering hydraulic cylinder selection, a detailed understanding of key technical parameters and performance metrics is essential. These specifications dictate a cylinder's suitability for a particular application, influencing its force output, speed, durability, and operational efficiency. The most fundamental parameters include bore size (internal diameter of the cylinder barrel), stroke length (the maximum distance the piston can travel), and piston rod diameter. These dimensions directly determine the cylinder's theoretical force output: greater bore size results in more force for a given pressure, while rod diameter affects the differential area for pull force in double-acting cylinders. Working pressure, measured in PSI or bar, defines the maximum allowable hydraulic pressure the cylinder is designed to safely operate under, and burst pressure indicates the absolute maximum pressure the cylinder can withstand before failure. Mounting types (e.g., clevis, trunnion, flange, spherical eye) are critical for proper integration into machinery and dictate how the cylinder transfers force and withstands side loads, influencing overall system stability and longevity.

Beyond these basic dimensions, several performance metrics provide deeper insights into a cylinder's operational characteristics. Efficiency, often overlooked, relates to how effectively hydraulic energy is converted into mechanical work, influenced by internal friction from seals and fluid viscosity. Leakage rates, both internal (past the piston seal) and external (past the rod seal), are critical indicators of seal integrity and overall cylinder health. Excessive leakage reduces efficiency and can lead to system contamination. Operating temperature range defines the ambient and fluid temperatures within which the cylinder can safely and efficiently function, considering the properties of hydraulic fluid and seal materials. The speed of operation, determined by flow rate and cylinder dimensions, is vital for applications requiring rapid movements, such as in automation or material handling. For specialized applications, additional parameters like cushioning at the end of the stroke (to reduce shock), integrated position sensors, or specialized coatings for corrosion resistance in harsh environments become significant. The Hydraulic Cylinder YG75200, for instance, is engineered with specific parameters to ensure optimal performance in its intended industrial applications, balancing force, speed, and durability.

To further illustrate typical parameters and provide a reference point for those examining a hydraulic cylinder video or product specifications, here is a table outlining common parameters relevant to various hydraulic cylinders, including characteristics often associated with models suitable for similar applications as the Hydraulic Cylinder YG75200. This data helps in preliminary hydraulic cylinder selection and comparison across different product offerings.

This table serves as a general guide, and specific product datasheets for models like the Hydraulic Cylinder YG75200 will provide precise figures. The detailed examination of these parameters is crucial for engineers designing new hydraulic systems or performing replacing hydraulic cylinder operations, ensuring that the chosen component not only fits physically but also performs optimally under the intended operational conditions. It underscores the technical expertise required in the hydraulic field and the importance of relying on comprehensive specifications from reputable manufacturers.

Diverse Application Scenarios and Compelling Case Studies

Hydraulic cylinders are the backbone of numerous industries, providing the linear force necessary for a vast array of operations. Their versatility, combined with their ability to generate immense power, makes them indispensable in sectors ranging from heavy construction and mining to precision manufacturing and agriculture. In construction, hydraulic cylinders power the booms, buckets, and outriggers of excavators, bulldozers, and cranes, enabling earthmoving, lifting, and demolition tasks with unparalleled strength and control. Similarly, in the mining industry, large-scale hydraulic cylinders operate massive haul trucks, shovels, and rock crushers, enduring extreme loads and harsh, abrasive environments. The robust design and high-pressure capabilities of products like the Hydraulic Cylinder YG75200 make them ideal for these demanding applications, where reliability and minimal downtime are paramount.

Agriculture significantly relies on hydraulic power to enhance productivity and efficiency. Agricultural hydraulic cylinders are integral to tractors, harvesters, planters, and sprayers, controlling implement depth, steering, and lifting mechanisms. Modern farming practices, increasingly reliant on precision agriculture, demand cylinders that offer precise control and durability under various weather conditions and soil types. For instance, a detailed hydraulic cylinder video might illustrate how a specific cylinder model ensures consistent plowing depth across uneven terrain, directly contributing to optimized crop yields. In manufacturing and material handling, hydraulic cylinders are crucial for presses, clamping devices, and lift tables, offering controlled force for assembly, fabrication, and material movement. Their inherent power density allows for compact system designs that can still deliver substantial force, optimizing floor space in production facilities.

Case studies further highlight the practical advantages and successful implementation of high-quality hydraulic cylinders. One notable example involves a large-scale steel mill that modernized its hot rolling line by replacing hydraulic cylinder components with custom-designed, heavy-duty cylinders featuring advanced sealing technologies and high-temperature resistance. The previous cylinders experienced frequent seal failures due to the extreme heat and continuous operation, leading to significant downtime and maintenance costs. The new cylinders, specifically engineered for metallurgical environments, drastically reduced leakage, improved operational uptime by 30%, and extended maintenance cycles from quarterly to annually, demonstrating the tangible benefits of proper hydraulic cylinder selection.

Another compelling case comes from the marine sector, where offshore oil rigs require reliable actuation for drill derricks and mooring systems. Here, cylinders must withstand highly corrosive saltwater environments and continuous dynamic loading. A project involving an offshore platform upgraded its outdated cylinders with specialized marine-grade units, which included stainless steel components and advanced anti-corrosion coatings. This upgrade eliminated recurring failures caused by rust and material fatigue, significantly enhancing safety and operational continuity. The Hydraulic Cylinder YG75200, designed for robustness and adaptability, exemplifies the kind of component that can be tailored for such demanding applications through careful material selection and surface treatments. These instances underscore not just the versatility of hydraulic cylinders but also the critical importance of selecting the right product engineered to the specific challenges of each application, showcasing the real-world experience and problem-solving capabilities provided by expert manufacturers.

Key Advantages of Advanced Hydraulic Cylinders and Manufacturer Comparison

Modern hydraulic cylinders offer a compelling set of advantages that make them the preferred choice for linear actuation in countless industrial applications. Firstly, their unparalleled power density means they can generate immense force within a relatively compact footprint, outperforming electromechanical alternatives in heavy-duty scenarios. This characteristic is particularly beneficial where space is constrained but high force output is critical, such as in mobile machinery or specialized manufacturing presses. Secondly, precision control is a hallmark of advanced hydraulic systems. With proportional valves and sophisticated feedback systems, hydraulic cylinders can achieve highly accurate positioning and speed control, essential for tasks requiring fine movements or synchronous operation, which a good hydraulic cylinder video often highlights through slow-motion demonstrations. Thirdly, their inherent durability and long service life stand out. Built from robust materials and designed to withstand high pressures, shocks, and vibrations, high-quality cylinders exhibit exceptional resilience, leading to lower total cost of ownership through reduced maintenance and replacement cycles. This robust nature is a direct result of meticulous design, advanced material science, and rigorous manufacturing processes, culminating in components that can operate reliably for years, even in the harshest environments.

Furthermore, energy efficiency has become a significant focus in hydraulic cylinder design. Innovations such as regenerative circuits, which reuse hydraulic fluid from the retracting side, and variable displacement pumps, which only supply fluid on demand, minimize energy waste. Reduced friction through advanced seal designs and optimized surface finishes also contributes to overall system efficiency, translating into lower operational costs and a smaller environmental footprint. The simplicity of maintenance, especially for modular designs or those with easily accessible seals, further enhances their appeal. For example, knowing when and how to perform a routine check or replacing hydraulic cylinder seals can significantly extend the life of the unit and prevent catastrophic failures. The Hydraulic Cylinder YG75200, like other top-tier cylinders, is designed to minimize frictional losses and maximize fluid efficiency, embodying these advanced principles.

When it comes to manufacturer comparison, several criteria differentiate a top-tier supplier from the rest. The first is an unwavering commitment to quality control, demonstrated through ISO certifications (e.g., ISO 9001, ISO 14001), rigorous testing protocols (e.g., 100% pressure testing, endurance testing), and traceable material sourcing. A reputable manufacturer will readily provide detailed technical specifications, test data, and material certificates. Secondly, strong R&D capabilities are crucial. Leading manufacturers continually invest in research to develop new materials, improve designs, and integrate smart technologies, ensuring their products remain at the forefront of innovation. For instance, advancements in sealing compounds for high-temperature applications or the development of integrated sensors for predictive maintenance are indicators of a forward-thinking manufacturer. Thirdly, comprehensive customer support, including pre-sales consultation, custom engineering capabilities, and responsive after-sales service, is vital. The ability to offer bespoke solutions for unique applications, adapting standard hydraulic cylinder types or designing entirely new ones, is a significant differentiator.

Finally, industry reputation, service longevity, and client testimonials serve as strong indicators of a manufacturer's reliability and trustworthiness. Companies with decades of experience and a broad portfolio of successful installations across diverse industries often possess the accumulated expertise to handle complex challenges and provide robust, long-lasting solutions. By meticulously evaluating these factors, B2B decision-makers can ensure they partner with a manufacturer capable of delivering high-performance, durable, and reliable hydraulic cylinders that meet their specific operational demands and contribute to long-term system efficiency and safety. The continuous pursuit of excellence in all these areas defines a manufacturer that truly offers authoritative and trustworthy solutions in the competitive hydraulic components market.

Maintenance, Troubleshooting, and Replacing Hydraulic Cylinder Components

Even the most robust hydraulic cylinders require diligent maintenance to ensure optimal performance, extend their operational lifespan, and prevent costly downtime. Preventive maintenance is paramount and typically involves regular inspection of the cylinder for external leaks, rod scoring, seal degradation, and mounting integrity. Checking hydraulic fluid levels and quality, and ensuring the filtration system is operating effectively, are also crucial, as contaminated or degraded fluid is a leading cause of cylinder failure and premature wear on seals and internal components. Periodic tightening of tie rods (for tie-rod cylinders) and ensuring proper lubrication of pivot points can prevent mechanical wear and maintain system efficiency. For agricultural hydraulic cylinders, particular attention must be paid to protecting piston rods from abrasive dirt and debris, which can quickly damage seals and rod surfaces. Implementing a proactive maintenance schedule based on operating hours or cycles, rather than reactive repairs, significantly reduces unexpected failures and extends the overall life of the equipment.

Troubleshooting common hydraulic cylinder issues often involves systematic diagnosis. Loss of force or slow operation might indicate internal leakage due to worn piston seals or bypass, or a problem with the hydraulic pump. External leakage points to worn rod seals or damaged barrel surfaces, requiring immediate attention to prevent fluid loss and environmental contamination. Jerky or erratic motion can be caused by air in the system (cavitation), bent piston rods, or damaged cylinder bores. Overheating of the cylinder or hydraulic fluid suggests excessive friction, undersized components, or a clogged return line. Diagnosing these issues often requires specialized tools and expertise, including pressure gauges, flow meters, and thermal imaging cameras. Manufacturers often provide detailed troubleshooting guides, and a comprehensive hydraulic cylinder video demonstrating diagnostic procedures can be an invaluable resource for maintenance teams, providing visual step-by-step instructions for identifying and addressing common malfunctions.

The decision to repair or replace a hydraulic cylinder, especially when considering a unit like the Hydraulic Cylinder YG75200, depends on several factors, including the extent of damage, the cost of repair versus replacement, and the cylinder's age and critical role in the system. For minor issues like seal replacement or superficial rod scoring, repair is often feasible and cost-effective. However, significant damage, such as a bent or severely scored piston rod, a deformed cylinder barrel, or extensive internal corrosion, typically warrants replacement. When replacing hydraulic cylinder components, it is critical to select a unit with identical or superior specifications to ensure compatibility and performance. Key considerations include bore and stroke dimensions, working pressure rating, mounting style, and port configurations. Upgrading to a more robust model with enhanced sealing technology or corrosion resistance, particularly if the original failure was due to environmental factors or material limitations, can also be a wise long-term investment.

The replacement process typically involves safely relieving hydraulic pressure, disconnecting hydraulic lines and mounting hardware, carefully removing the old cylinder, and installing the new one. Proper alignment during installation is critical to prevent binding and premature wear. After installation, the system must be bled to remove any trapped air, and function-tested under varying loads to ensure correct operation and absence of leaks. Access to original equipment manufacturer (OEM) specifications or a trusted supplier's expertise is invaluable during the hydraulic cylinder selection and replacement phases, guaranteeing that the new component integrates seamlessly and performs reliably for its intended service life. This systematic approach to maintenance, troubleshooting, and replacement highlights the commitment to operational excellence and underscores the trustworthiness of manufacturers who provide comprehensive support throughout the product lifecycle.

Trust and Support: FAQs, Warranty, and Customer Service

Building and maintaining trust with B2B clients in the hydraulic industry goes beyond just delivering high-quality products. It encompasses providing transparent information, robust support, and dependable after-sales service. A well-structured Frequently Asked Questions (FAQ) module is an essential tool for addressing common queries from engineers, technicians, and procurement specialists. This resource typically covers topics such as: What are the main hydraulic cylinder types and their applications? How do I determine the correct bore and stroke for my application? What are the standard mounting options? How often should hydraulic cylinders be serviced? What are the signs of a failing cylinder seal? Can a bent piston rod be repaired? What considerations are paramount when replacing hydraulic cylinder components in an existing system? These questions, and their comprehensive answers, serve to demystify technical aspects, expedite decision-making, and build confidence in the manufacturer's expertise. Furthermore, detailed product documentation, including user manuals, installation guides, and technical drawings, provides invaluable support throughout the product's lifecycle, ensuring correct operation and maintenance.

A clear and transparent warranty commitment is another cornerstone of trustworthiness. For products like the Hydraulic Cylinder YG75200, a typical warranty period might range from 12 to 24 months, covering defects in materials and workmanship under normal operating conditions. The warranty terms should clearly outline what is covered, what voids the warranty (e.g., improper installation, unauthorized modifications, operating beyond specified parameters), and the procedure for filing a claim. This provides clients with peace of mind, knowing their investment is protected and that the manufacturer stands behind the quality of their product. Coupled with warranty, reliable delivery protocols and realistic lead times are critical for project planning and operational continuity. Manufacturers should provide clear information on their production capacity, typical delivery schedules, and options for expedited shipping, especially for critical spare parts or urgent project requirements. Timely delivery minimizes project delays and ensures that operations are not disrupted by component shortages, a factor often highlighted in customer feedback discussions or in a detailed hydraulic cylinder video showcasing efficient logistics.

Beyond formal policies, exceptional customer support distinguishes leading manufacturers. This includes a responsive technical support team capable of offering expert advice on hydraulic cylinder selection, troubleshooting complex issues, and guiding clients through custom solution development. Accessibility through multiple channels—phone, email, dedicated online portals—ensures that assistance is readily available when needed. Furthermore, ongoing support, such as training programs for client maintenance teams, periodic technical bulletins on product enhancements, or updates on industry best practices for agricultural hydraulic cylinders or other specialized types, further solidifies the partnership. This holistic approach to customer service, spanning from pre-sales consultation to post-delivery support, underscores a manufacturer's commitment to long-term client success and reinforces their authority and trustworthiness in the highly specialized field of hydraulic technology. It transforms a transactional relationship into a collaborative partnership, essential for complex industrial operations.

Conclusion and Future Outlook in Hydraulic Technology

The hydraulic cylinder, a seemingly simple device, represents a pinnacle of engineering precision and power. Its critical role in converting hydraulic pressure into linear force underpins the operation of countless industrial, agricultural, and mobile machines, driving productivity and innovation across diverse sectors. From the initial stages of meticulous material selection and advanced manufacturing processes, through rigorous quality control and comprehensive testing, every aspect of a high-quality hydraulic cylinder's creation is designed to ensure exceptional durability, reliability, and performance. Understanding the myriad of hydraulic cylinder types, their specific technical parameters, and their advantages in various application scenarios is fundamental for any professional involved in system design, procurement, or maintenance. The strategic considerations involved in hydraulic cylinder selection are paramount, as choosing the right component directly impacts operational efficiency, safety, and long-term cost of ownership, making a thorough review, potentially aided by a detailed hydraulic cylinder video, a crucial step.

Looking ahead, the hydraulic industry is poised for continuous evolution, driven by advancements in smart technologies, the demand for increased energy efficiency, and the integration of predictive maintenance capabilities. Future innovations will likely see more widespread adoption of integrated sensors for real-time data acquisition, advanced materials for extreme environments, and sophisticated control systems that enable even greater precision and automation. The emphasis will remain on developing solutions that are not only powerful and robust but also environmentally sustainable and economically viable for B2B stakeholders. By partnering with manufacturers who demonstrate profound expertise, practical experience, undisputed authoritativeness through certifications and proven track records, and unwavering trustworthiness in their support and guarantees, businesses can ensure they are equipped with cutting-edge hydraulic solutions that meet the demands of today and anticipate the challenges of tomorrow. The continuous dedication to innovation, quality, and customer-centric approaches will undoubtedly shape the next generation of hydraulic cylinders, solidifying their indispensable position in the global industrial landscape. This forward-looking perspective, coupled with a deep understanding of current capabilities, positions businesses to make strategic decisions that enhance operational resilience and competitive advantage.

References and Further Reading:

- Hydraulics & Pneumatics: Understanding Hydraulic Cylinder Types and Their Applications (Provides in-depth technical details on various cylinder configurations and their operational contexts.)

- Machine Design: How to Select a Hydraulic Cylinder (Offers practical guidance on critical parameters and decision-making for cylinder procurement.)

- National Fluid Power Association (NFPA): Industry Statistics (Source for market trends and growth drivers in the fluid power industry.)

-

Tandem Hydraulic Pump for Multi - Function SystemsNewsJul.16,2025

-

Selecting The Right Hydraulic Motor TypeNewsJul.16,2025

-

How Air Directional Control Valves Power Your Pneumatic WorldNewsJul.16,2025

-

Engine Cooling Pump Bearing Noise CausesNewsJul.16,2025

-

Double-Ended Hydraulic Cylinder in Steel Rolling MillsNewsJul.16,2025

-

Design Optimization for Efficient Metal CastingsNewsJul.16,2025

-

Unveiling the Power and Precision of Hydraulic CylindersNewsJul.16,2025