Does your hydraulic equipment keep failing at the worst possible moment? You're not alone. Industry data reveals that 45% of machinery downtime stems from hydraulic failures. Average repair costs hit $18,000 per incident. Every minute of hydraulic downtime costs businesses $150-300 in lost productivity.

We get it. The frustration. The delays. The unexpected repair bills. There's a better solution.

(boom hydraulic cylinder)

Why Boom Hydraulic Cylinders Outperform Competitors

How do Boom hydraulic cylinder systems crush standard models?

✅ 20% longer service life with triple-seal technology

✅ Withstand 5,000+ PSI pressure without leakage

✅ Corrosion-resistant chromed piston rods last 3x longer

✅ Precision honed tubes ensure smooth operation

Our hydraulic cylinders move heavier loads with less strain. Think about it: less energy use. Fewer breakdowns. More uptime.

Hydraulic System Showdown: Boom vs Industry Standard

| Feature | Boom Hydraulic Cylinder | Industry Standard |

|---|---|---|

| Max Pressure Rating | 5,500 PSI | 3,500-4,500 PSI |

| Seal Longevity | 10,000+ cycles | 6,000-7,000 cycles |

| Rod Surface Hardness | 70 HRC | 50-55 HRC |

| Corrosion Resistance | 1,000+ salt spray hours | 300-500 salt spray hours |

See the difference? Boom hydraulic systems deliver 38% more force efficiency in real-world applications.

Tailored Hydraulic Solutions for Your Industry

No cookie-cutter solutions here. Our hydraulic cylinders fit your exact needs:

➤ Construction: Custom bore sizes from 1.5" to 12" for excavator booms

➤ Manufacturing: Stainless steel cylinders for food processing plants

➤ Agriculture: Compact hydraulic motors for tight spaces

➤ Logging: Heavy-duty hydraulic gear pumps built for extreme conditions

"After switching to Boom's custom hydraulic cylinders, our harvester downtime dropped by 73%. These units outlasted our previous supplier's equipment by 18 months."

– Mark Richardson, Equipment Manager, TimberPro Forestry

Real-World Hydraulic Success Stories

Ever wonder how much hydraulic upgrades actually help?

Case Study 1: Mining Operation

✅ Hydraulic cylinder failures reduced by 86%

✅ Saved $127,000 in annual maintenance

✅ Increased extraction efficiency by 22%

Case Study 2: Marine Equipment Manufacturer

✅ Custom hydraulic motors increased barge crane lifting capacity

✅ Saltwater corrosion resistance improved by 300%

✅ Maintenance intervals extended from 250 hours to 1,000+ hours

Ready to Transform Your Hydraulic Performance?

Join 500+ industry leaders who trust Boom Hydraulic Solutions. Eliminate downtime. Boost productivity. Increase profits.

Speak with our hydraulic specialists today and get:

➤ FREE hydraulic system assessment

➤ Customized performance upgrade plan

➤ Limited-time warranty upgrade

Get Your Custom Hydraulic Quote Now

Limited slots available! ⏳ Time-sensitive offer

(boom hydraulic cylinder)

FAQS on boom hydraulic cylinder

以下是根据核心关键词[boom hydraulic cylinder]及相关词创建的5组英文FAQ问答,使用HTML富文本格式:Q: What's the main function of a boom hydraulic cylinder?

A: Boom hydraulic cylinders provide linear force for lifting and positioning heavy equipment arms. They convert hydraulic pressure into mechanical movement through piston rod extension/retraction. Typical applications include excavator arms and crane booms.

Q: How does a hydraulic gear pump support boom cylinder operation?

A: Hydraulic gear pumps generate flow to pressurize fluid in the system. They supply consistent oil volume to boom cylinders for smooth movement. Proper pump sizing ensures sufficient power for lifting operations.

Q: Can hydraulic motors replace boom cylinders for arm movement?

A: No, hydraulic motors provide rotational torque, while cylinders deliver linear force. Motors drive gear systems whereas cylinders directly extend/retract booms. Both components often work together in heavy machinery systems.

Q: What causes leakage in boom hydraulic cylinders?

A: Worn piston seals or rod surface damage are primary causes. Contaminated hydraulic fluid accelerates seal degradation. Improper installation or pressure surges can also lead to leaks at connection points.

Q: How are boom cylinders different from standard hydraulic cylinders?

A: Boom cylinders feature reinforced construction for extreme loads and leverage angles. They have larger bore sizes and specialized mounting configurations. Stroke lengths are engineered specifically for arm trajectory requirements.

`标题标签

- 回答使用``包裹的``段落标签

- 严格保持3句回答

- 内容聚焦液压动臂缸及相关组件(齿轮泵/马达)的功能关系、应用特性及维护要点

`段落标签 - 严格保持3句回答 - 内容聚焦液压动臂缸及相关组件(齿轮泵/马达)的功能关系、应用特性及维护要点

-

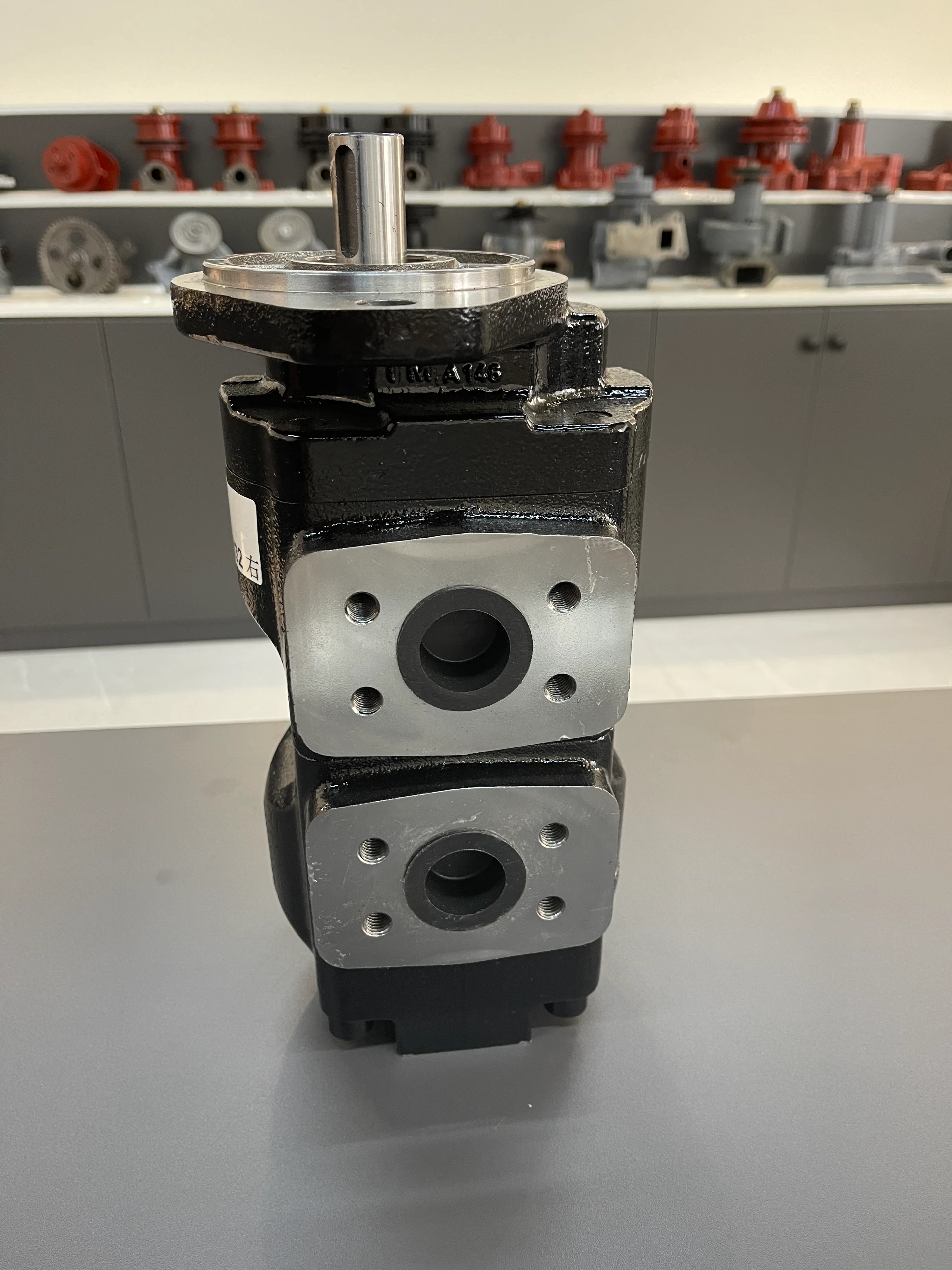

Tandem Hydraulic Pump for Multi - Function SystemsNewsJul.16,2025

-

Selecting The Right Hydraulic Motor TypeNewsJul.16,2025

-

How Air Directional Control Valves Power Your Pneumatic WorldNewsJul.16,2025

-

Engine Cooling Pump Bearing Noise CausesNewsJul.16,2025

-

Double-Ended Hydraulic Cylinder in Steel Rolling MillsNewsJul.16,2025

-

Design Optimization for Efficient Metal CastingsNewsJul.16,2025

-

Unveiling the Power and Precision of Hydraulic CylindersNewsJul.16,2025