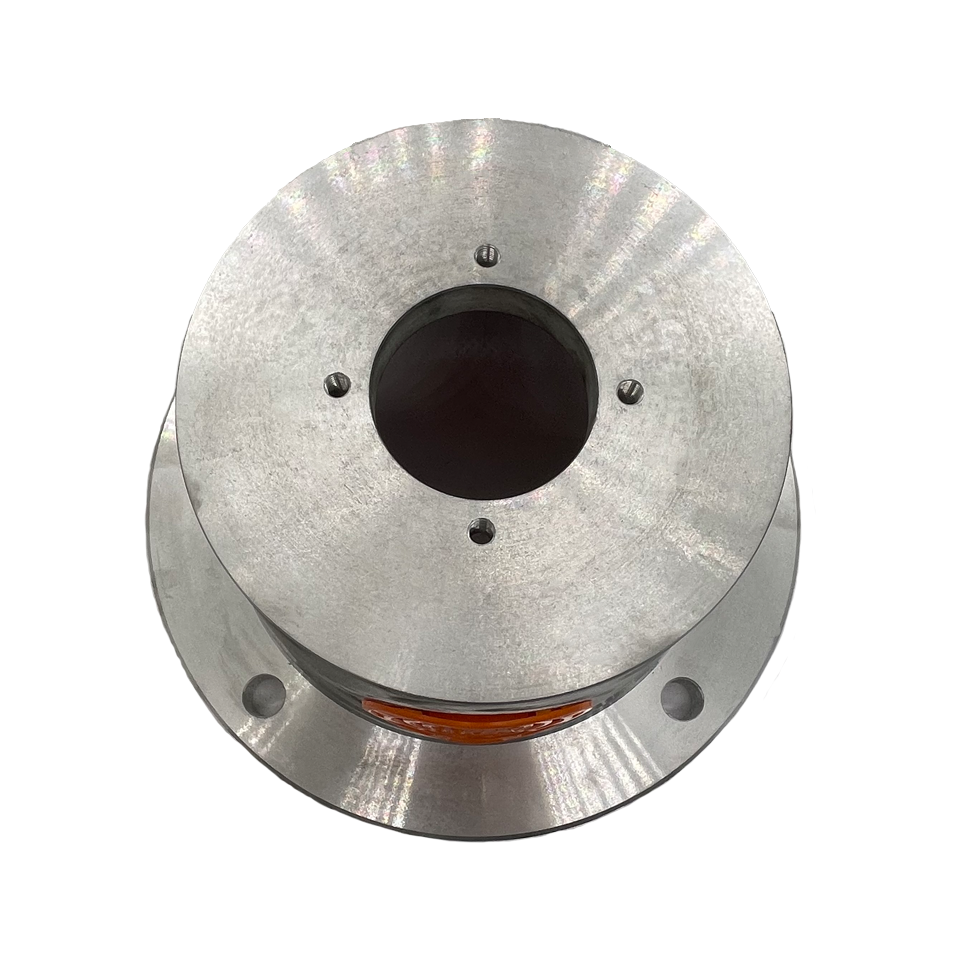

'n Koppelstuk is 'n meganiese toestel wat gebruik word om twee asse of ander roterende dele te verbind om krag of beweging van die een na die ander oor te dra. Die primêre funksie daarvan is om 'n betroubare verbinding tussen komponente te verskaf, om te verseker dat die rotasie en wringkrag wat deur die aandryfmeganisme gegenereer word na die aangedrewe masjinerie of toerusting oorgedra word. Koppelstukke kan in 'n wye reeks nywerhede gebruik word, insluitend motor, vervaardiging en kragopwekking. Daar is verskeie tipes koppelings, elk ontwerp vir spesifieke doeleindes, soos rigiede, buigsame en vloeibare koppelings. Rigiede koppelings word gebruik wanneer presiese belyning noodsaaklik is, en hulle laat geen beweging of buigsaamheid tussen die gekoppelde asse toe nie. Buigsame koppelings, aan die ander kant, is ontwerp om wanbelyning of geringe asbewegings te akkommodeer as gevolg van termiese uitsetting, vibrasie of vervaardigingstoleransies. Dit word algemeen gebruik in masjinerie waar as wanbelyning onvermydelik is. Vloeistofkoppelings gebruik hidrouliese vloeistof om wringkrag oor te dra en laat glip tussen die gekoppelde asse toe, wat 'n gladde kragoordrag verskaf en die risiko van meganiese skok verminder. Die keuse van koppelingtipe hang af van verskeie faktore, soos die tipe las, spoed, wanbelyningstoleransie en skokabsorpsiebehoeftes. Koppelstukke is noodsaaklik in baie meganiese stelsels, en die keuse daarvan speel 'n deurslaggewende rol in die handhawing van die werkverrigting, doeltreffendheid en lewensduur van die toerusting. Behoorlik gekose koppelings verminder ook slytasie op gekoppelde komponente, wat help om voortydige mislukking te voorkom en die bedryfslewe van masjiene te verleng.

What Are the Different Types of Couplings?

There are several different types of couplings, each designed for specific applications and operating conditions. Rigid couplings are one of the most basic types and are used when the shafts being connected are precisely aligned. These couplings do not accommodate any misalignment and transmit torque directly between the shafts. They are often used in applications where shafts are perfectly aligned, such as in gearboxes or when connecting motors to pumps. Flexible couplings, in contrast, are designed to absorb misalignment between connected shafts. These couplings allow for slight angular, parallel, or axial misalignment, and are ideal for systems where misalignment can occur due to thermal expansion, vibration, or small inaccuracies in manufacturing. Types of flexible couplings include elastomeric, bellows, and jaw couplings. Elastomeric couplings use flexible elements made from rubber or elastomers, which help to dampen vibrations and reduce shock loads. Bellows couplings use a metal bellows to allow for angular, axial, and lateral misalignment while offering high torsional stiffness and low backlash. Jaw couplings have two hubs with a flexible elastomeric insert that fits between them, allowing for easy installation and accommodating moderate misalignment. Fluid couplings operate on the principle of hydraulic fluid being used to transmit torque between shafts, allowing for smooth power transfer and reducing the effects of shock load or mechanical stress. Fluid couplings are widely used in applications where variable speed control is required, such as in conveyors and automotive transmissions. Universal couplings or U-joints are commonly used in automotive and heavy equipment applications, where the angle between the shafts can change as the vehicle or machinery moves. The choice of coupling type depends on factors such as the amount of misalignment, the level of torque transfer required, and whether shock load or vibration damping is necessary.

What Is the Purpose of a Coupling?

The primary purpose of a coupling is to connect two rotating shafts or parts and transmit power or torque between them. By doing so, couplings enable the transfer of mechanical energy from one component to another, making them essential in the operation of motors, pumps, conveyors, and other machinery. In addition to transmitting power, couplings serve several other important functions, such as accommodating misalignment between connected shafts, compensating for axial, angular, or radial displacement, and providing vibration isolation. In many cases, couplings are designed to reduce the risk of damage to connected machinery by absorbing shock loads or dampening vibrations. For example, in systems with motors and pumps, couplings help ensure that any vibrations caused by motor rotation or pump operation do not get transmitted to other sensitive components, thus reducing wear and tear and extending the life of the equipment. Couplings can also provide flexibility by allowing slight movements or misalignments between parts without causing mechanical damage. In situations where the shafts are not perfectly aligned or where thermal expansion occurs, flexible couplings can help maintain the connection and prevent stress buildup. Another key function of some types of couplings, such as fluid couplings, is to provide smooth power transmission, enabling the gradual transfer of torque without sudden shocks or interruptions. By fulfilling these roles, couplings improve the efficiency, reliability, and longevity of mechanical systems, ensuring that machines and equipment perform optimally under various operating conditions.